High Gloss Laminate Flooring: The Ultimate Guide for Modern Commercial and Residential Spaces

High Gloss Laminate Flooring: The Ultimate Guide for Modern Commercial and Residential Spaces

High gloss laminate flooring has emerged as a premier choice for architects, contractors, and property developers worldwide. This innovative surfacing solution combines the opulent visual appeal of polished stone or lacquered hardwood with the unparalleled durability, cost-effectiveness, and ease of maintenance inherent to advanced laminate technology. For B2B buyers sourcing materials for large-scale residential projects, hospitality venues, retail spaces, or office complexes, understanding the nuances of this product category is crucial for making informed procurement decisions that balance aesthetics, performance, and budget.

Industry Background and Evolving Market Dynamics

The laminate flooring industry has undergone a significant transformation over the past decade. Once considered a purely utilitarian alternative to solid wood, modern laminate, particularly the high gloss laminate flooring segment, now competes directly with high-end materials. The driving force behind this shift is continuous technological innovation in digital printing and embossing techniques, which allow for stunningly realistic reproductions of natural materials.

The global demand for high gloss finish laminate boards is fueled by several interconnected factors. In commercial design, there is a growing preference for environments that feel spacious, clean, and infused with light. The reflective quality of a high gloss surface naturally amplifies ambient light, making it ideal for lobbies, showrooms, and smaller retail units. Simultaneously, in the residential sector, contemporary minimalist and Scandinavian design trends champion sleek, reflective surfaces that convey a sense of modernity and effortless style.

Current Market Data and Growth Projections

According to recent market analyses, the global laminate flooring market is projected to grow at a CAGR of 5.8% from 2023 to 2030, with high gloss variants capturing a significant share due to their aesthetic and functional appeal. Europe remains a dominant consumer and innovation hub, closely followed by rapid growth in the Asia-Pacific region, particularly in commercial real estate development. North America shows sustained demand, especially in the multifamily housing and retail renovation sectors. This growth is underpinned by the product's value proposition: achieving a luxury look without the prohibitive cost and maintenance of polished concrete or high-gloss solid wood.

Key Trends Shaping the High Gloss Laminate Sector

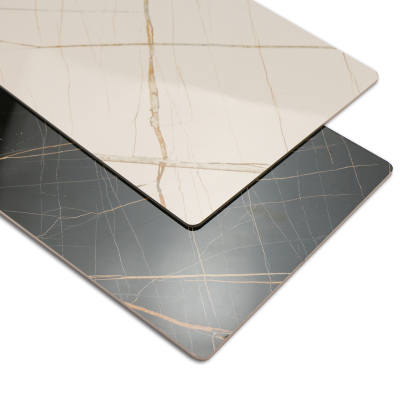

Hyper-Realistic Designs and Textures: The latest high gloss laminate flooring planks go beyond simple shine. Manufacturers utilize high-definition photographic layers to replicate the intricate veining of marble, the subtle grain variations of exotic hardwoods, and even abstract geometric patterns. Synchronized embossing—where the texture matches the printed design—adds a tactile depth that is virtually indistinguishable from the real material.

Enhanced Durability and Performance: The focus is on creating surfaces that can withstand high-traffic commercial environments. Trends include:

Superior Wear Layers: Advancements in aluminum oxide and ceramic bead technologies have led to AC5 and AC6 rated abrasion class products, offering exceptional resistance to scratches, scuffs, and stains.

Waterproof and Water-Resistant Cores: The rise of waterproof high gloss laminate flooring with solid polymer cores or moisture-resistant high-density fiberboard (HDF) cores has expanded applications to kitchens, bathrooms, and basements, mitigating traditional concerns about moisture.

Sustainability as a Standard: B2B buyers increasingly mandate environmentally responsible products. Leading suppliers now offer sustainable high gloss laminate flooring with cores sourced from responsibly managed forests, low-VOC (Volatile Organic Compound) adhesives, and full compliance with international standards like CARB ATCM Phase 2 and E1/E0 emissions regulations. Many products are also fully recyclable at end-of-life.

Large Format Planks: The trend towards wider and longer planks continues, reducing visible seams and creating a more seamless, expansive visual flow—a perfect complement to the reflective gloss finish.

Technical Breakdown: Anatomy of a High Gloss Laminate Board

Understanding the multi-layer construction is key to evaluating quality. A premium high gloss laminate wood flooring panel is engineered in four distinct layers:

Wear Layer (Overlay): This transparent, melamine-based top coat is the workhorse. Its thickness and composition determine the Abrasion Class (AC) rating. For high gloss variants, this layer is meticulously processed to achieve a perfectly smooth, reflective surface without compromising scratch resistance.

Decorative Layer: A high-resolution photograph printed on saturating paper. This defines the visual design—be it white gloss, black gloss, or wood-effect high gloss laminate flooring.

Core Layer: Typically composed of high-density fiberboard (HDF) for dimensional stability and impact resistance. For waterproof gloss laminate flooring, the core is often treated or replaced with a waterproof polymer composite.

Backing Layer (Stabilizer): A melamine or resin-saturated layer that provides moisture balance, prevents warping, and sometimes includes an attached underlayment for sound dampening.

Two primary manufacturing processes are used:

Direct Pressure Laminate (DPL): The most common method, where all layers are fused simultaneously under high heat and pressure. This produces a highly durable product suitable for most applications.

High-Pressure Laminate (HPL): Used for ultra-heavy-duty commercial flooring. Here, the wear and decorative layers are first fused into a single, incredibly tough sheet under extreme pressure before being bonded to the core. High-pressure laminate (HPL) construction offers the highest resistance to indentation and moisture.

Application and Installation Considerations

For successful project deployment, proper subfloor preparation (dry, level, and clean) is non-negotiable. Most modern high gloss laminate flooring suppliers provide products with intuitive click-lock installation systems, enabling efficient floating floor installations suitable for DIY or professional fitting. In commercial settings, adherence to the manufacturer's recommended installation guidelines and use of appropriate commercial underlayments are critical for longevity and warranty validation.

FAQ: Answers for B2B Buyers

Q1: How durable is high gloss laminate flooring in a commercial retail environment?

Extremely durable when the correct product is specified. For high-traffic retail spaces, look for products with an AC5 (heavy commercial) or AC6 (extra heavy commercial) abrasion rating. The hard wear layer protects the decorative surface from foot traffic, rolling chairs, and minor impacts. Regular maintenance with recommended cleaners will preserve the gloss finish for years.

Q2: Does the high gloss finish show scratches and footprints easily?

Modern scratch-resistant high gloss laminate incorporates advanced anti-scratch technologies in the wear layer. While any glossy surface may show occasional footprints or dust more readily than a matte finish, the actual surface is highly scratch-resistant. For settings where minimal visible smudging is paramount, consider a "silk-matt" or semi-gloss variant, which offers a softer sheen.

Q3: Is waterproof high gloss laminate truly suitable for wet areas?

Yes, the latest generation of 100% waterproof laminate flooring features a solid polymer or stone-plastic composite (SPC) core that is impervious to water. Unlike traditional HDF-core laminate, these products can withstand prolonged exposure to moisture, including spills and humidity, making them ideal for commercial kitchens, bathrooms, and entryways. Always verify the product's specific waterproof warranty claims.

Q4: What is the typical lead time and minimum order quantity (MOQ) when sourcing?

This varies by supplier and customization level. Standard items from large high gloss laminate flooring manufacturers may have shorter lead times (2-4 weeks) and MOQs ranging from 500 to 1000 square meters per SKU. For custom designs, colors, or thicknesses, lead times can extend to 8-12 weeks, with higher MOQs. Always confirm these terms during the quotation process.

The market for high gloss laminate flooring is defined by a powerful synergy of design sophistication and rigorous engineering. For B2B buyers, the opportunity lies in leveraging this versatile material to deliver projects that impress visually, perform reliably under pressure, and align with budgetary and sustainability goals. By partnering with a reputable manufacturer that invests in R&D and quality control, you secure not just a product, but a long-term solution for your most demanding projects.