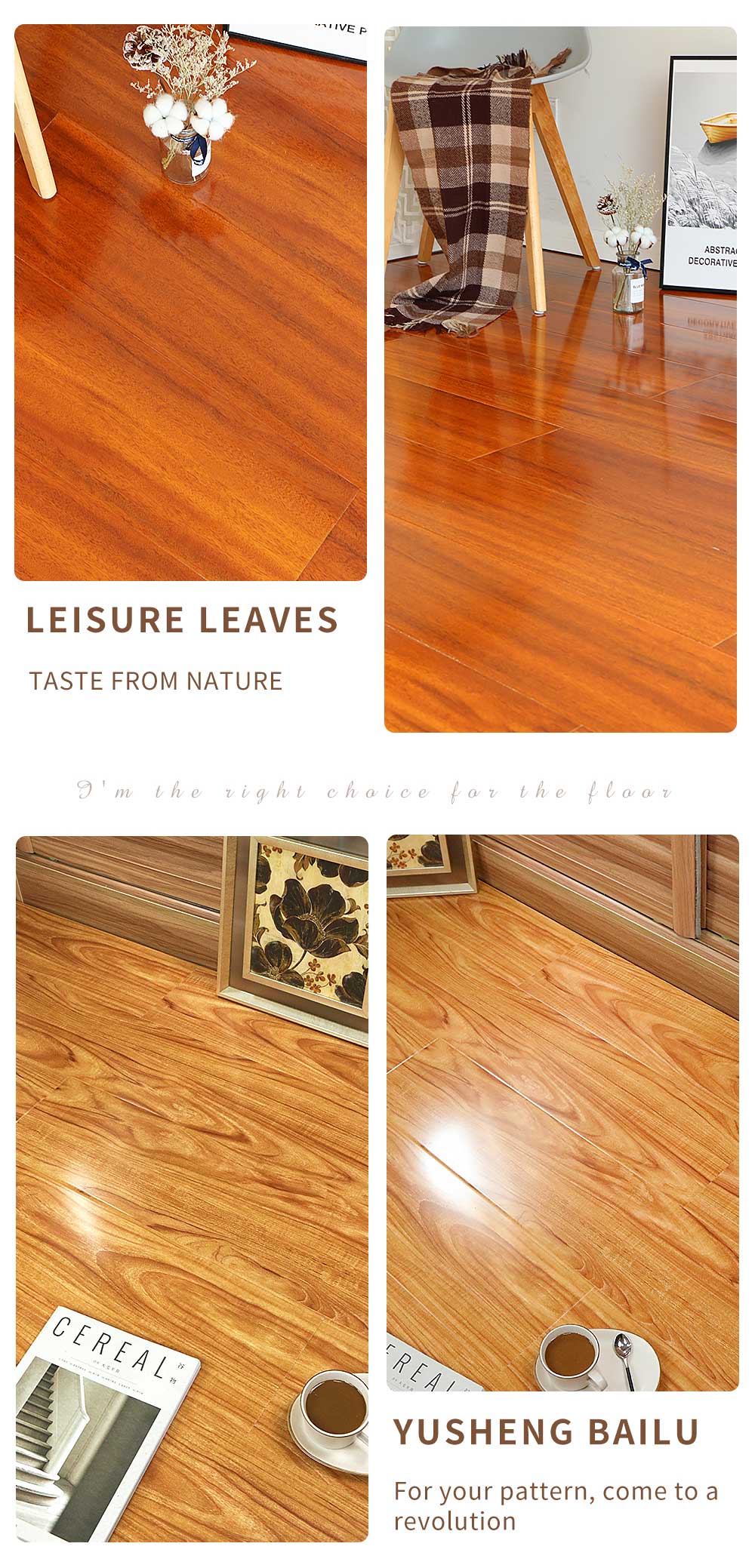

High Gloss Laminate Flooring

Product Features of Laminate Flooring:

1.Cost-effective alternative to hardwood, stone, or tile.

2.Durable, resistant to scratches, stains, and fading for high-traffic areas.

3.Easy click-lock installation.

4.Low maintenance with minimal cleaning.

5.Variety of designs to mimic natural materials.

6.Some options are water-resistant for kitchens and bathrooms.

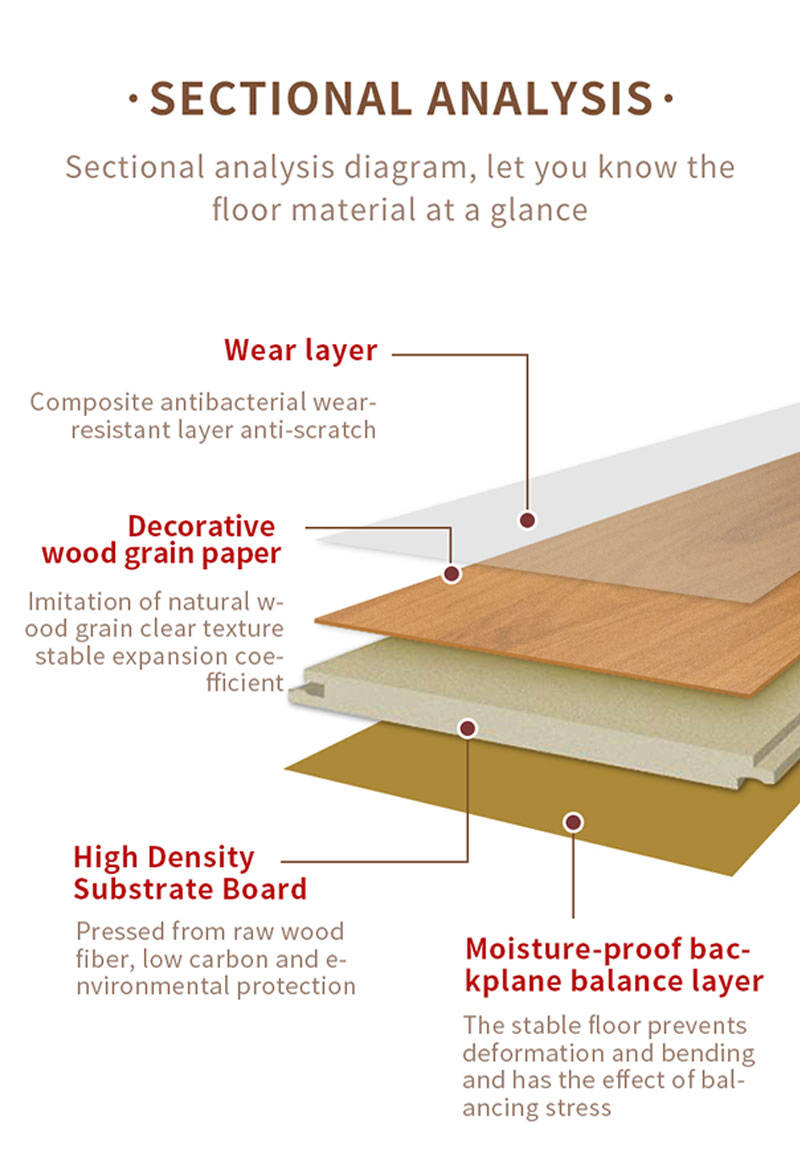

Product Introduction: Laminate Flooring Structure

High-performance laminate flooring features a precision-engineered four-layer composition:

Wear-Resistant Overlay

Decorative Surface Layer

High-Density Core Substrate

Stabilizing Backer (moisture barrier)

Also designated as resin-impregnated laminated wood flooring, these products incorporate cross-linked thermosetting melamine resins within their composite structure, with premium grades utilizing multiple resin-saturation treatments for enhanced durability.

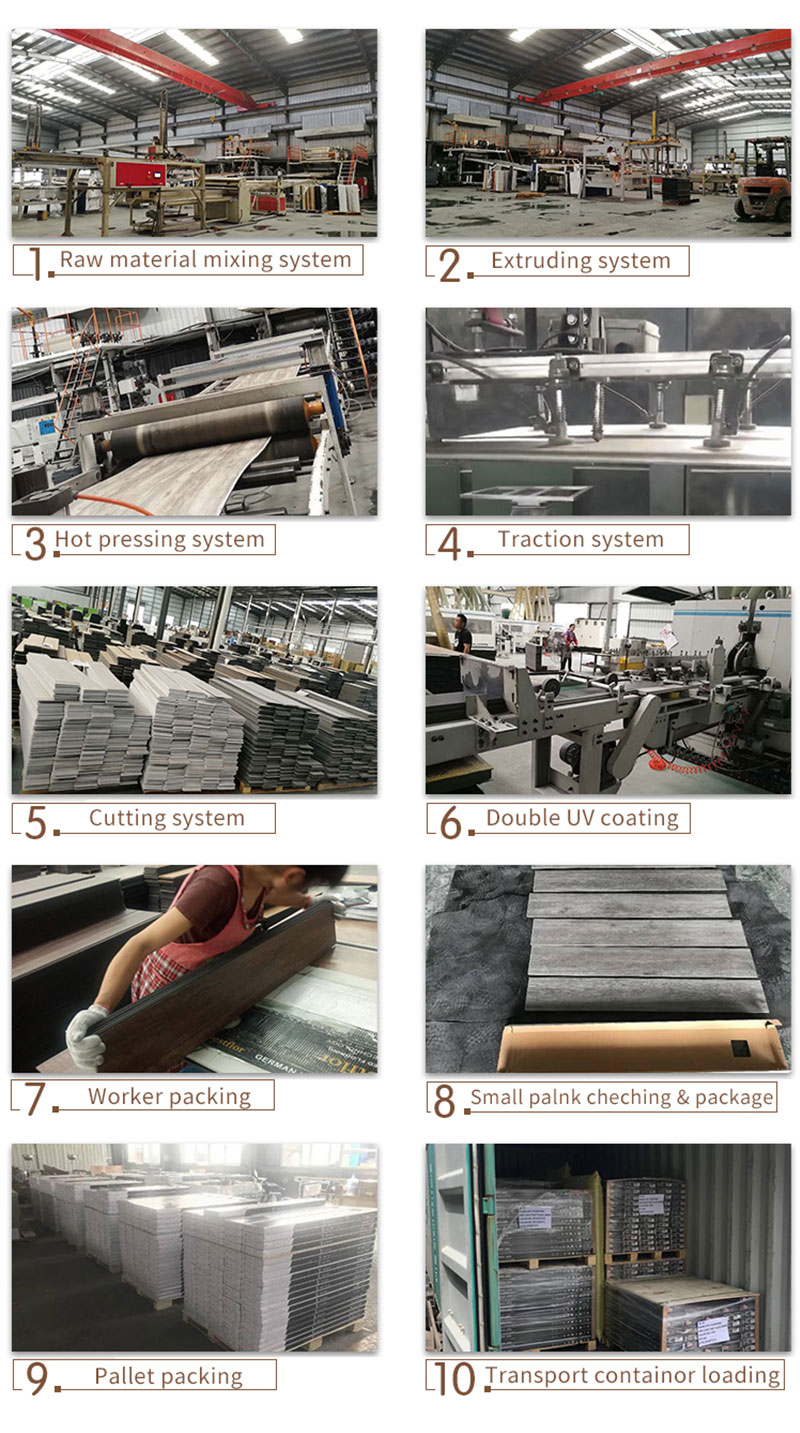

/ Factory direct sales / AAA Grade plate / Environmental Protection / 20 Years warranty /

Sectional Analysis | ||||

Wear Layer | Composite antibacterial wear-resistant layer anti-scratch. | |||

Decorative Wood Grain Paper | lmitation of natural wood grain clear texture stable expansion coefficient. | |||

High Density Substrate Board | Pressed from raw wood fiber,low carbon and environmental protection. | |||

Moisture-proof Backplane Balance Layer | The stable floor prevents deformation and bending and has the effect of balancing stress. | |||

Parameters

Specifications with card slot | 1225*207*12mm | ||||||||

Thickness | 12mm | ||||||||

Wear layer | AC4 | ||||||||

Quantity | 11pcs/Carton | ||||||||

Area | 2.3581m³ | ||||||||

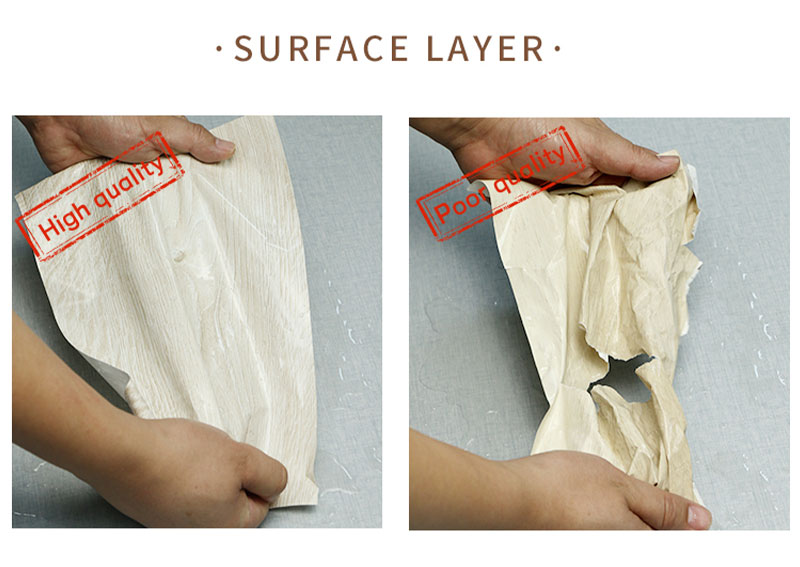

High quality | Poor quality | ||||||||||

Log color | Color black | ||||||||||

HDF | Recycled material is | ||||||||||

Environmental | Pungent add leaves | ||||||||||

Protection | Branches | ||||||||||

High quality | Poor quality | ||||||||||

Soaked hands cannot tear | The surface wil brokenwhen it gets wet | ||||||||||

High-end custom | Small factory production | ||||||||||

VE high-end surface | Engineering use | ||||||||||

Stable and not discolored-lored | Discoloration deforma-tion | ||||||||||

Get a certificate of honor;

《Certificate of compliance》

《CCTV-7 honorary exhibition brand》

《China forest certification enterprise》

《Quality management system certification》

《China environmental labeling productcertification certificate》

《Innovation Award for the l0th anniversary ofChina's forest products industry》

《10th anniversary contribution award of China'sforest products industry》

《Assured fidelity products and brand protectionproducts in the national consumer market》

FREQUENTLY ASKED QUESTIONS

I. PRODUCT PERFORMANCE

Q: What is the abrasion resistance rating of laminate flooring?

A: Premium laminate flooring incorporates aluminum oxide-enhanced wear layers with AC ratings (Abrasion Class per EN 13329). This engineered surface resists scuffing from foot traffic and furniture movement while maintaining aesthetic integrity, delivering extended service life in residential applications.

Q: How does laminate flooring perform in humid conditions?

A: Our laminate products feature high-density fiberboard cores with moisture-resistant resins and sealed locking systems, providing superior dimensional stability. While designed to withstand ambient humidity, prolonged water exposure should be avoided. Immediate drying of spills is recommended to prevent moisture ingress through plank joints.

Q: Are laminate flooring products environmentally compliant?

A: All products meet E1 formaldehyde emission standards (≤0.124 mg/m³ per GB 18580-2017) and are certified under international environmental protocols including CARB Phase

II. INSTALLATION & MAINTENANCE

Q: What are the installation requirements for laminate flooring?

A: Laminate flooring utilizes click-lock installation systems suitable for floating floor applications. Professional installation requires:

Subfloor flatness tolerance: ≤3mm/2m

Relative humidity: 35-65%

Temperature: 15-27°C

10mm perimeter expansion gaps

These measures prevent thermal expansion issues and ensure optimal performance.

Q: What are the proper maintenance procedures?

A: Recommended maintenance protocol:

Daily: Dry microfibre dust mopping

Weekly: Damp mopping with pH-neutral cleaner

Incident response: Immediate spot cleaning

Avoid:

Excessive water application

Abrasive cleaning tools

Alkaline or solvent-based cleaners

This preserves surface integrity and extends product lifespan.