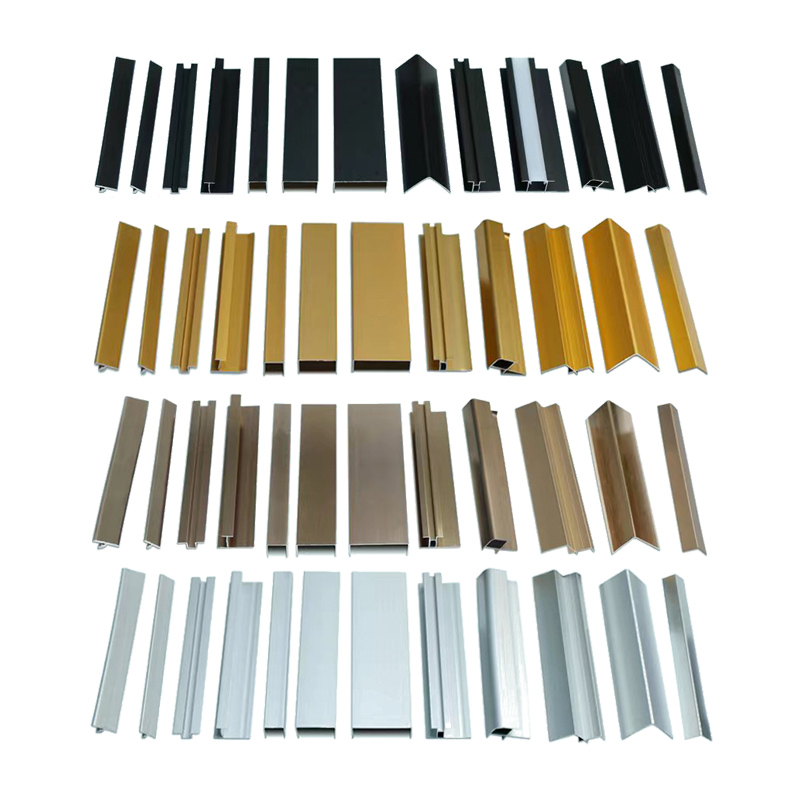

Aluminum Profiles

Aluminum alloy strip advantages:

Light weight and high strength, lower than common metal, easy to handle and install, and by alloying and heat treatment, high strength, suitable for a variety of uses.

Corrosion resistance, the surface is easy to produce dense oxide film, can resist moisture, acid and alkali corrosion, long life.

Easy processing, good plasticity, can be made of various shapes and sizes by a variety of processes to meet the needs of different scenes.

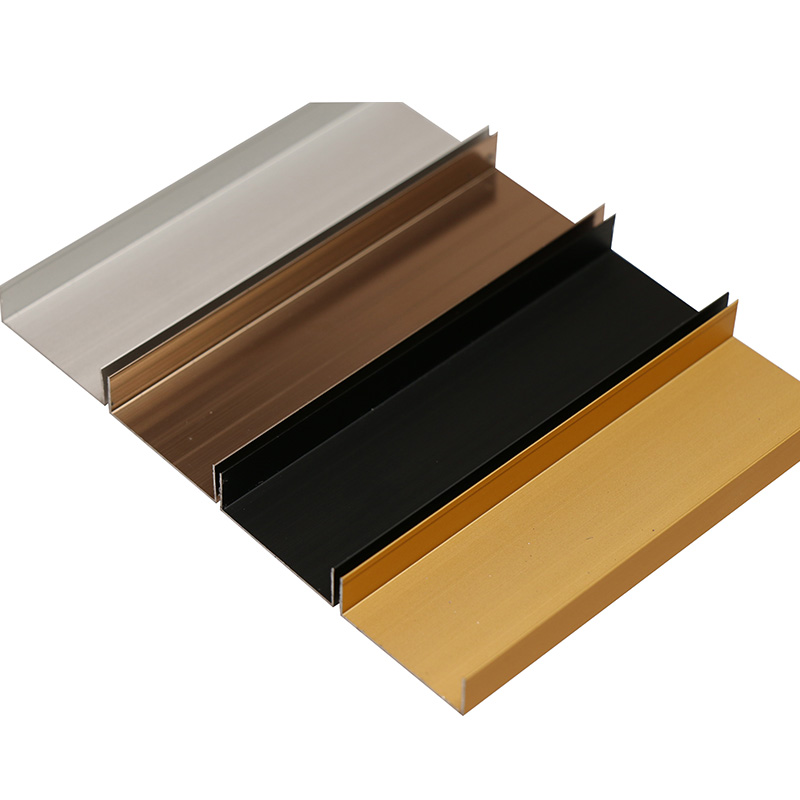

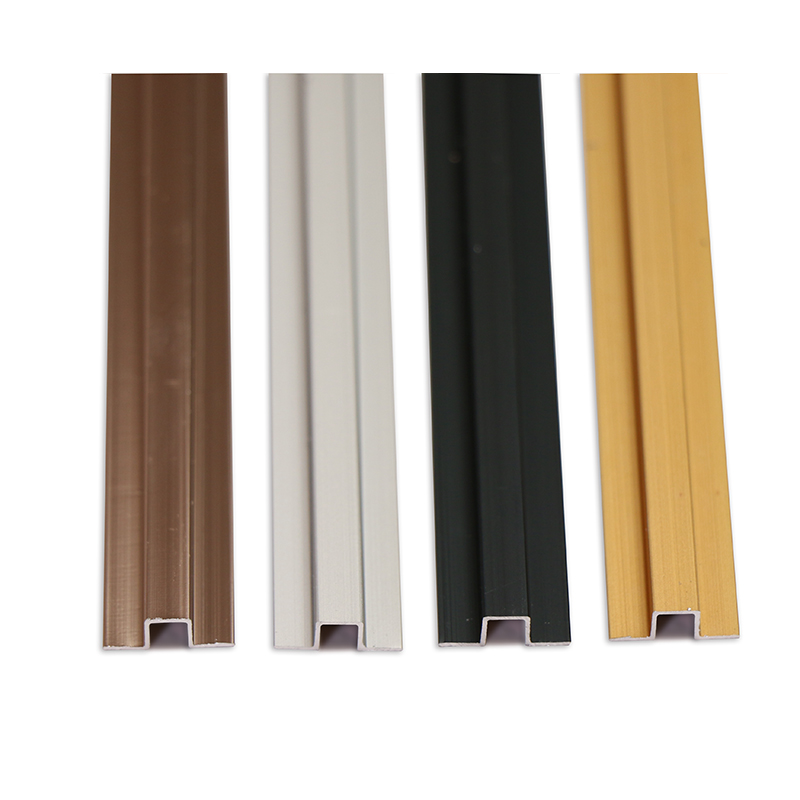

Beautiful and durable, diverse surface treatment process, rich color, decorative, wear-resistant weather, not easy to fade.

Environmental protection can be recycled, recycling energy consumption is low, only about 5% of the primary aluminum production energy consumption, conducive to resource conservation and environmental protection.

Good thermal conductivity and electrical conductivity, suitable for electronic equipment radiator, electrical line wire and other areas that have requirements for thermal conductivity and electrical conduction.

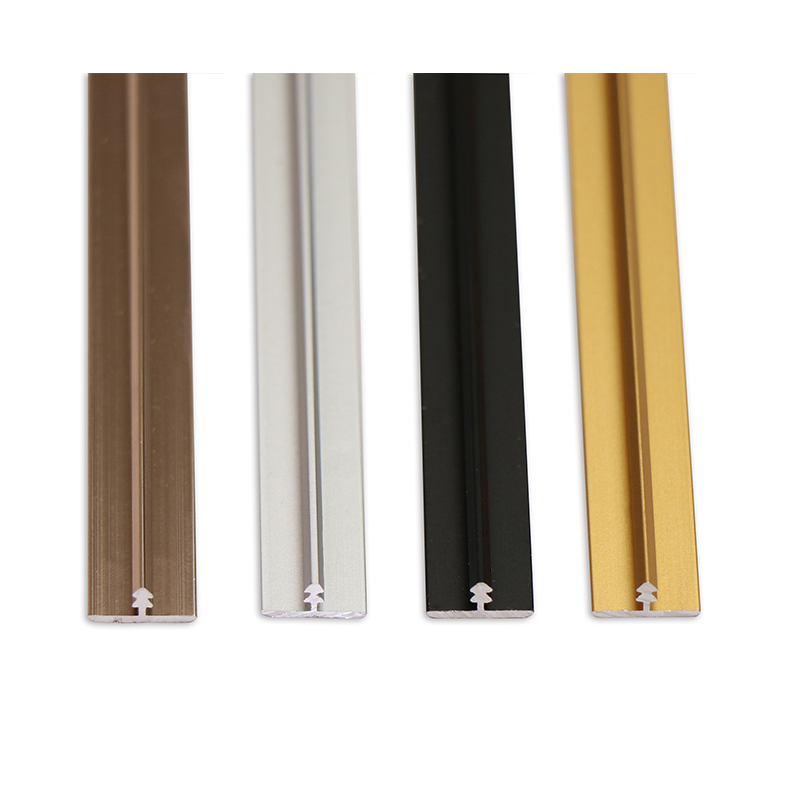

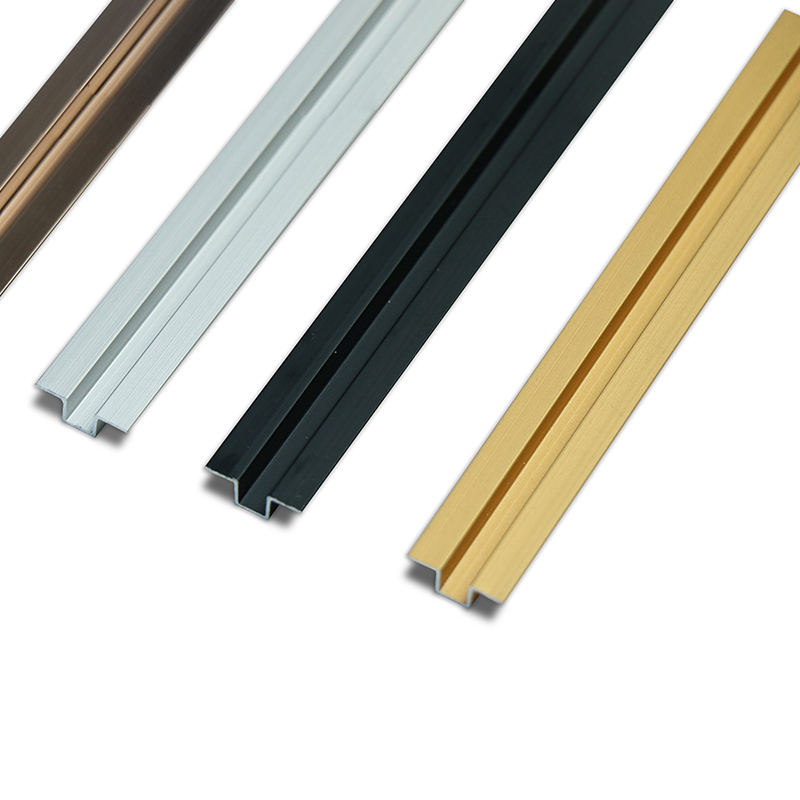

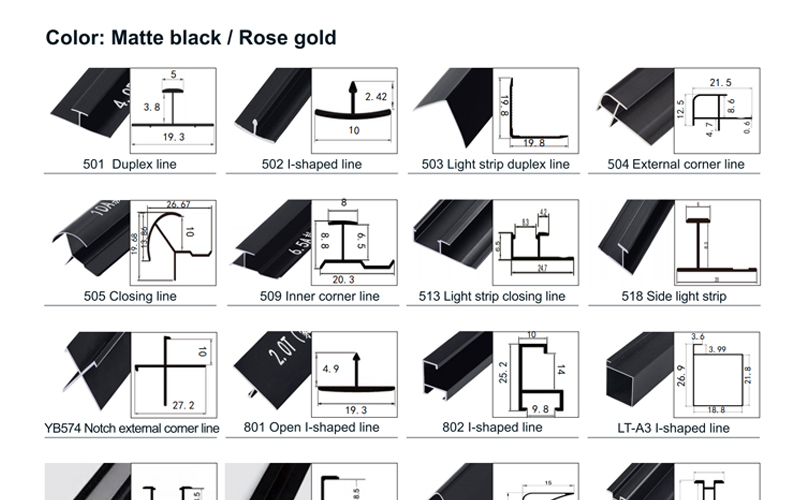

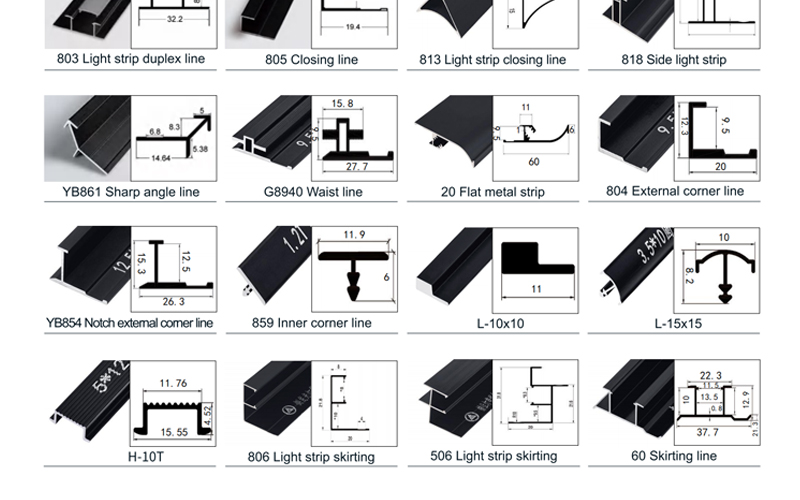

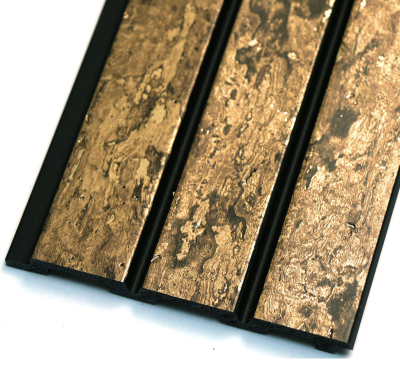

Wall panel closing strips, also known as closing strips or wrapping strips, mainly focus on concealing and beautifying the joints between wall and floor materials. In this way, they successfully solve the problem of those sharp and unattractive corners.

These strips have the great ability to connect two different materials. By providing a covering, they make sure the building materials stay flat and stable. They not only present an attractive way to cover up corner gaps, but also come with practical functions. For example, they can make the transitions look nice and keep different materials firmly in place.

Regarding product parameters

The application scenarios of wall panel closing strips are truly broad. They are widely used in various areas:

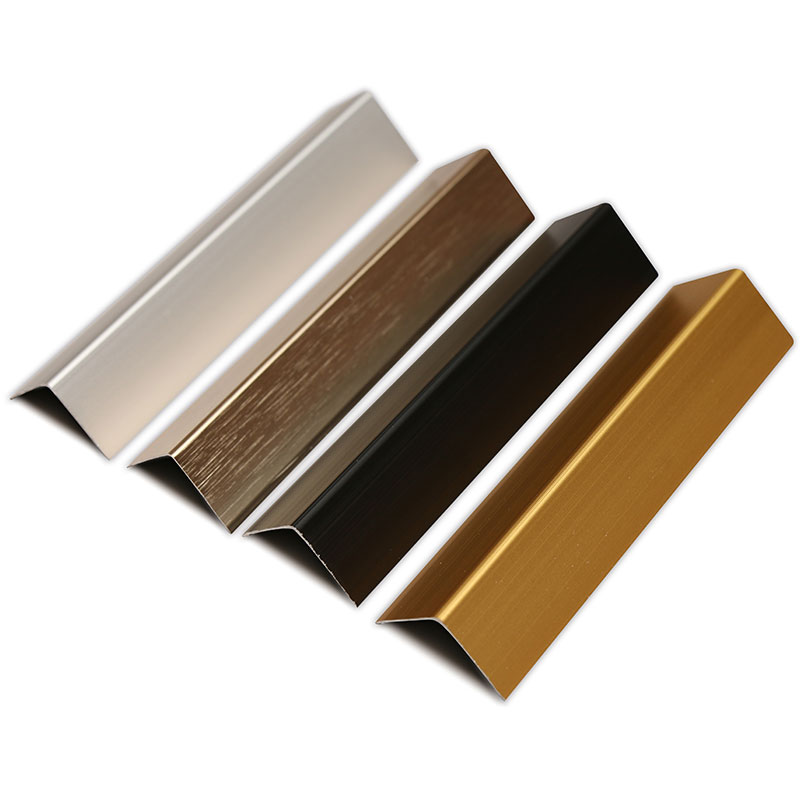

Corners: Whether at the corners where walls meet or where walls and floors connect, these closing strips are used to beautify and perfect the surfaces. They turn the originally rough and unappealing angles into smooth ones, enhancing the overall visual charm.

Yin and Yang Angles and Edge Angles: When applied to such positions, they make the overall look more harmonious and pleasing. They help different sections blend together smoothly, creating seamless and attractive transitions.

Connection of Different Materials: During wall decoration, when working with the connection of different wall materials, we need special materials to ensure both beauty and firmness. That's where the wall panel closing strips prove useful. They offer a reliable way to join disparate materials while maintaining an elegant appearance.

Floor Materials: For floor materials like wood flooring and ceramic tiles, these strips are used for edge treatment. They reinforce the stability of the flat veneer on both sides of the floor, respecting potential shifting or damage and ensuring a long-lasting, even finish.

FAQ:

1. Appearance and Durability

Where does the surface color of aluminum alloy metal strips originate?

The surface color is achieved through advanced technologies such as anodic oxidation, electrophoretic coating, and powder spraying, providing a wide range of colors to meet aesthetic requirements.

How long can it last for outdoor use?

Due to its wear-resistant surface and excellent weather resistance, it can maintain good color integrity under prolonged exposure to strong sunlight, wind, and rain. The specific longevity varies depending on the processing technology and environmental conditions but generally lasts for several years.

2. Environmental Protection Features

Is the aluminum alloy metal strip environmentally friendly?

Aluminum alloy metal strips are environmentally friendly due to their strong recyclability. Recycling consumes only about 5% of the energy required for primary aluminum production, significantly reducing resource waste and aligning with sustainable development principles.

Can it be recycled into metal strips?

After recovery, aluminum alloy metal strips can be reprocessed through smelting and manufacturing into new metal strips or other products, maintaining reliable quality.

3. Quality and Maintenance

How can the quality of aluminum alloy metal strips be evaluated?

Quality assessment involves checking if the surface is smooth and free from defective bubbles, measuring bending resistance to evaluate strength, and inspecting the density and uniformity of the oxide film, which relates to corrosion resistance.

Does it require special maintenance?

Special maintenance is generally not required. Under normal environmental conditions, occasional dust removal is sufficient. For more severe dirt, mild cleaning agents can be used while avoiding strong acid or alkali-based cleaners.