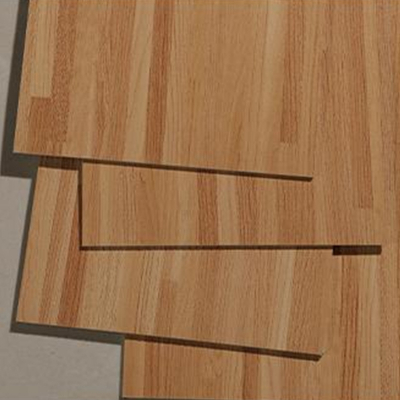

Engineered Hardwood Flooring

Durability: Solid three-layer structure, effectively reduce warping and bending, durable.

Moisture Resistance: Excellent moisture resistance, suitable for both indoor and outdoor environments.

Eco-Friendly: The use of recycled wood fiber and sustainable materials, practice the concept of environmental protection.

Low Maintenance: Low maintenance cost, can effectively resist fading, cracking and chipping.

Aesthetic Appeal: Smooth surface, showing natural wood appearance, beautiful and generous.

Cost-Effective: Long service life, reduce the frequency of replacement, cost-effective.

Thermal Insulation: Good thermal insulation performance, help energy-saving projects.

Engineered Hardwood Flooring: The Advanced Solution for Global Projects

Overview of Engineered Hardwood Flooring

Engineered hardwood flooring represents a sophisticated category of floor covering that combines aesthetic appeal with exceptional performance. Unlike solid hardwood, engineered wood floors are constructed using a multilayer composition, typically featuring a premium real wood veneer atop a cross-ply core substrate. This innovative structure provides dimensional stability, making it suitable for a wider range of installations and environments. As a premier choice for commercial and high-end residential projects, engineered flooring delivers the timeless beauty of natural wood with enhanced durability and practical versatility.

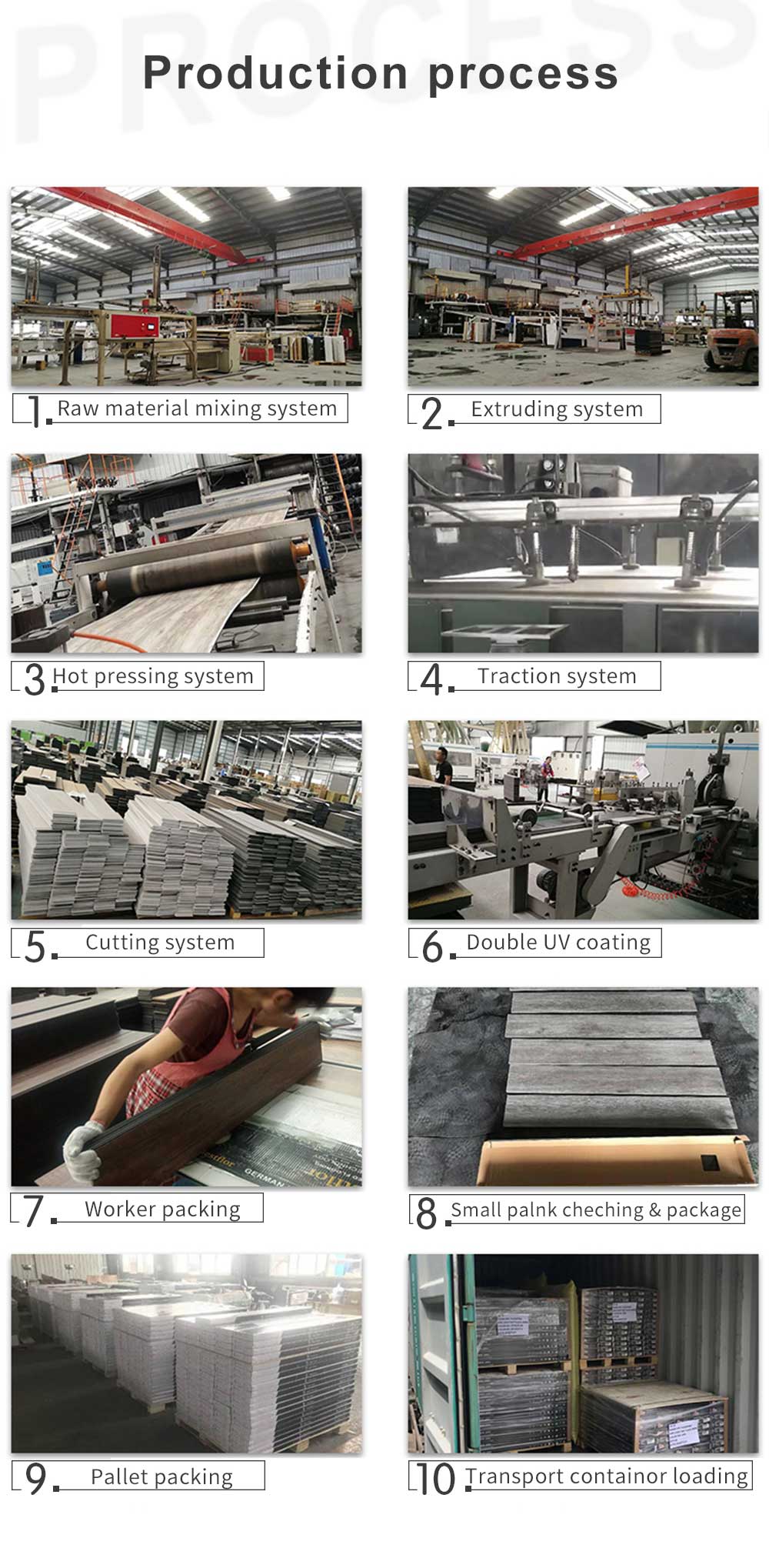

Multilayer Structure for Enhanced Stability

The core strength of engineered hardwood flooring lies in its precision-engineered cross-ply construction. Each plank consists of a top wear layer of genuine hardwood, a stabilizing core layer—often composed of high-density plywood or HDF—and a balancing back layer. This configuration effectively counteracts the natural tendency of wood to expand and contract with humidity and temperature fluctuations. The result is a remarkably stable engineered wood floor that performs reliably over concrete subfloors, with underfloor heating systems, and in regions with variable climates, minimizing the risk of warping or gapping.

Name | Three-layer parquet | ||||||||||

Brand | DELIN | ||||||||||

Size | 1220*20311236*2001620-110 | ||||||||||

Packaging specifications | 10pcs/Carton 2.472m²/10pcs/Carton 2.477m²/30pcs/Carton 1.987m² | ||||||||||

Durable years | 20 years | ||||||||||

Thickness | 12/15mm | ||||||||||

Surface technics | Diamond wear laver | ||||||||||

Main material | Wear layer | ||||||||||

Commodity inspection | E0 environmental protection,floor heating dedicated | ||||||||||

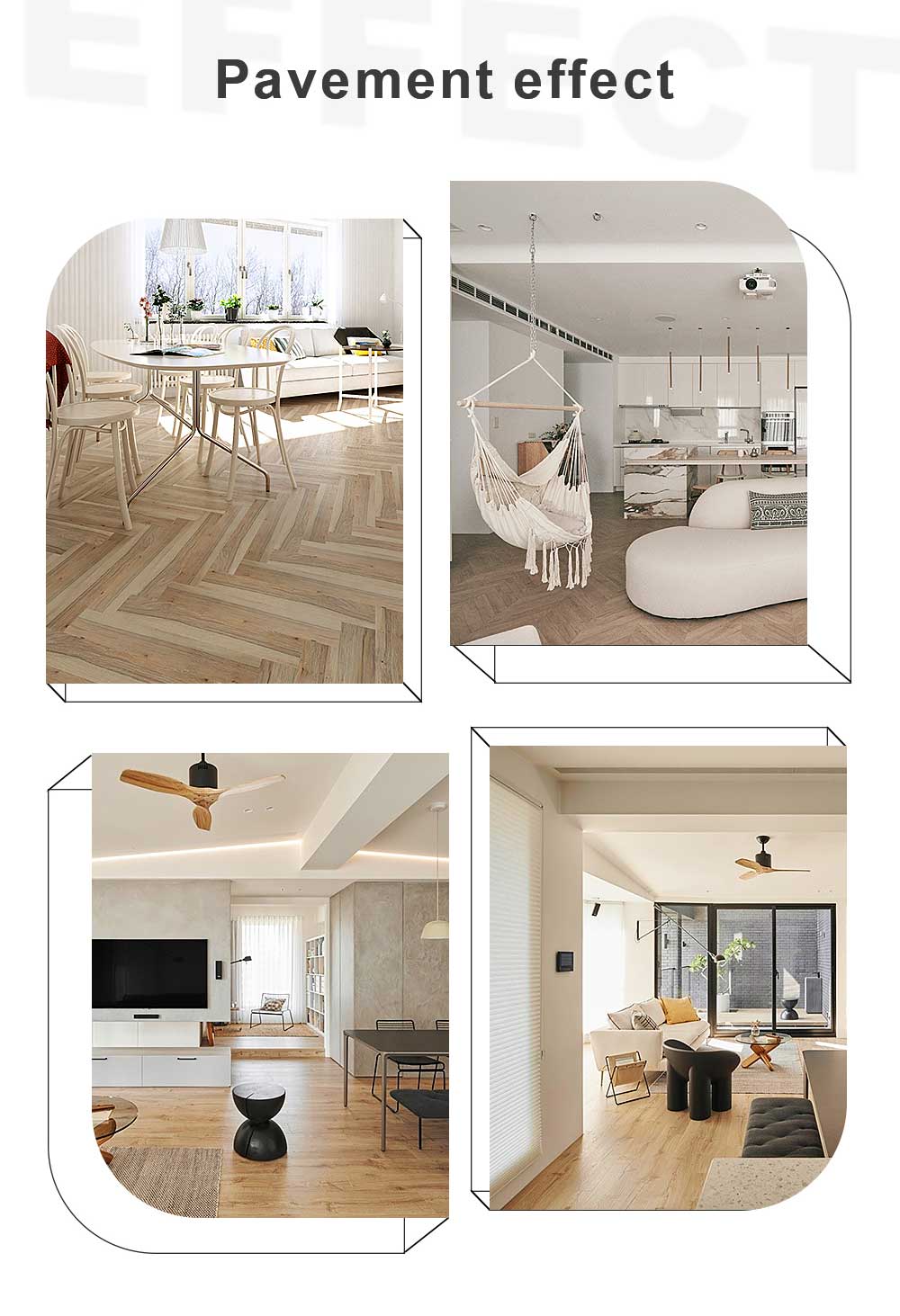

Applications & Ideal Use Cases

Engineered hardwood flooring is the specification-grade solution for projects where both aesthetics and performance are paramount. Its stability makes it ideal for installation in:

Commercial Spaces: Retail stores, boutique hotels, office lobbies, and professional workplaces.

Multi-Family Residential: Apartments and condominiums, particularly those above grade level or with concrete subfloors.

Renovation Projects: Direct installation over existing flooring substrates, simplifying and accelerating renovation timelines.

Global Export Markets: Its engineered stability ensures consistent performance in diverse international climates, from humid coastal regions to drier inland areas.

Design Versatility & Aesthetic Range

Modern manufacturing enables an extensive selection of wood species, finishes, textures, and plank dimensions. From classic European oak and North American walnut to exotic species, the real wood veneer offers authentic grain patterns and natural character. Finishes range from matte and satin to hand-scraped and wire-brushed textures, catering to diverse design schemas from minimalist contemporary to rustic traditional. This versatility makes engineered wood flooring a flexible design tool for architects, contractors, and specifiers.

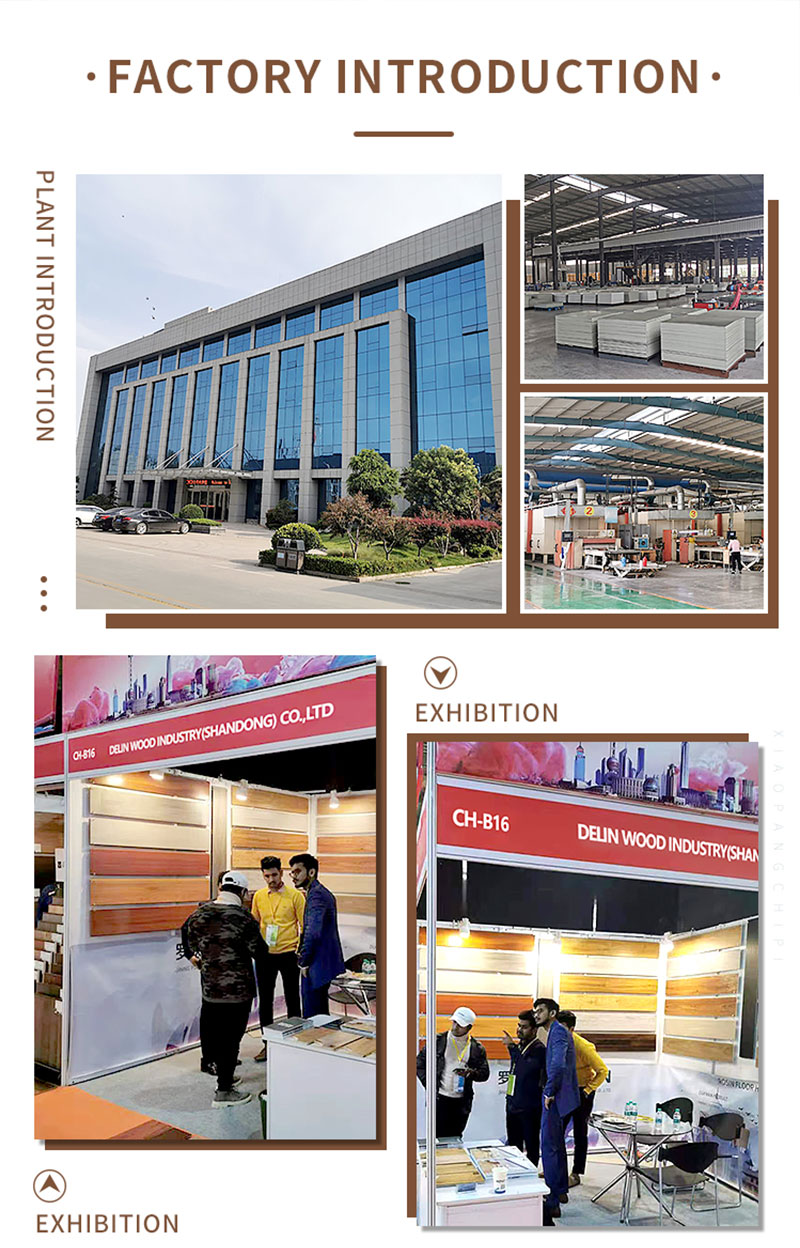

Delin Wood Industry: Your Trusted Manufacturing Partner

Delin Wood Industry (Shandong) Co., Ltd., established in 2010, has evolved into a fully integrated, large-scale manufacturer of premium flooring solutions. Our state-of-the-art facility, spanning over 300,000 square meters, is equipped with the most advanced specialized machinery dedicated to the production of laminate, engineered hardwood, and SPC vinyl flooring. With a skilled workforce of more than 100 employees and a robust monthly production capacity of 500,000 square meters, we are positioned to fulfill large-volume international orders efficiently.

Our commitment to excellence is validated by ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and SGS certifications, ensuring that every batch of our engineered wood flooring meets stringent international standards for quality, consistency, and environmental responsibility. We offer buyers access to hundreds of color and style options, backed by competitive pricing and a reputation built on reliability and superior product quality in both domestic and global markets.

FAQ: Frequently Asked Questions for B2B Buyers

Q1: How does the stability of engineered hardwood compare to solid hardwood for international shipping and installation?

A1: Engineered hardwood flooring is vastly superior for export and installation in varied climates. Its cross-ply structure minimizes dimensional movement, reducing the risk of issues related to moisture absorption during transit or after installation in environments with differing humidity levels compared to the country of manufacture.

Q2: What is the typical thickness of the real wood wear layer, and can the floors be refinished?

A2: Wear layer thickness varies by product grade, typically ranging from 2mm to 6mm. Products with a wear layer of at least 3mm can generally be sanded and refinished 2-3 times, significantly extending the floor's lifespan and protecting your investment.

Q3: Is engineered hardwood flooring compatible with underfloor heating (UFH) systems?

A3: Yes, most engineered wood floors are an excellent and recommended choice for use with radiant heating systems due to their inherent stability. It is crucial to follow the manufacturer's specific installation guidelines regarding maximum temperature and proper acclimation to ensure optimal performance.

Q4: What are the primary installation methods for engineered hardwood floors?

A4: The three main methods are: Floating (planks are clicked or glued together over an underlayment, not attached to the subfloor), Glue-Down (full-spread adhesive bonds the planks directly to the subfloor), and Nail-Down/Staple-Down (for wood subfloors). The best method depends on the subfloor type, project scale, and performance requirements.