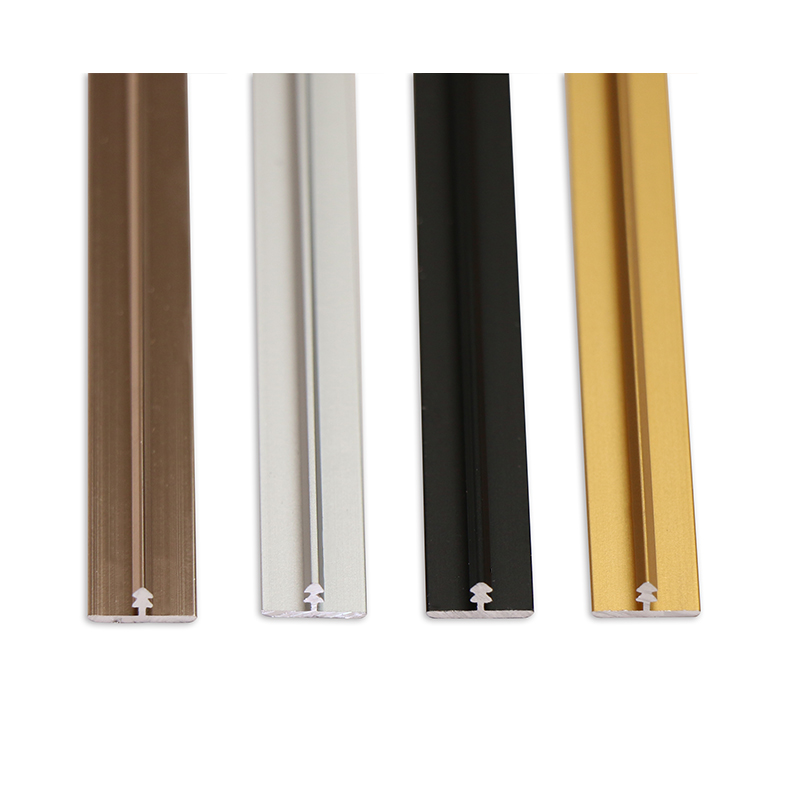

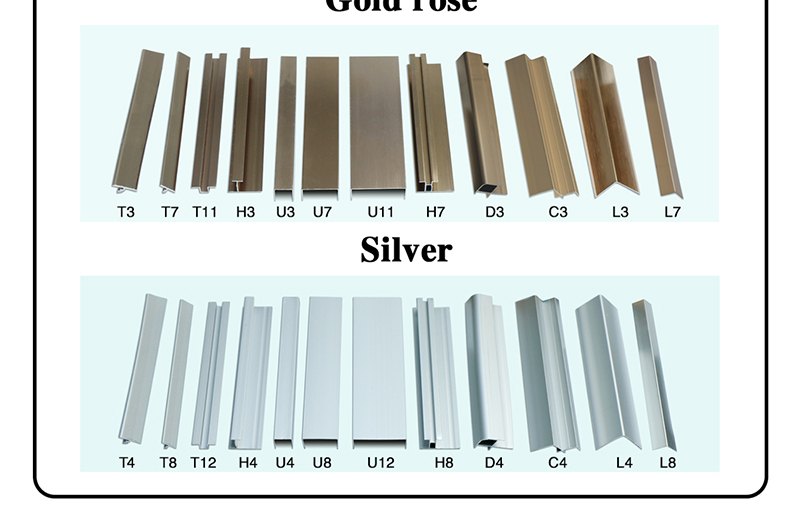

T- Moulding

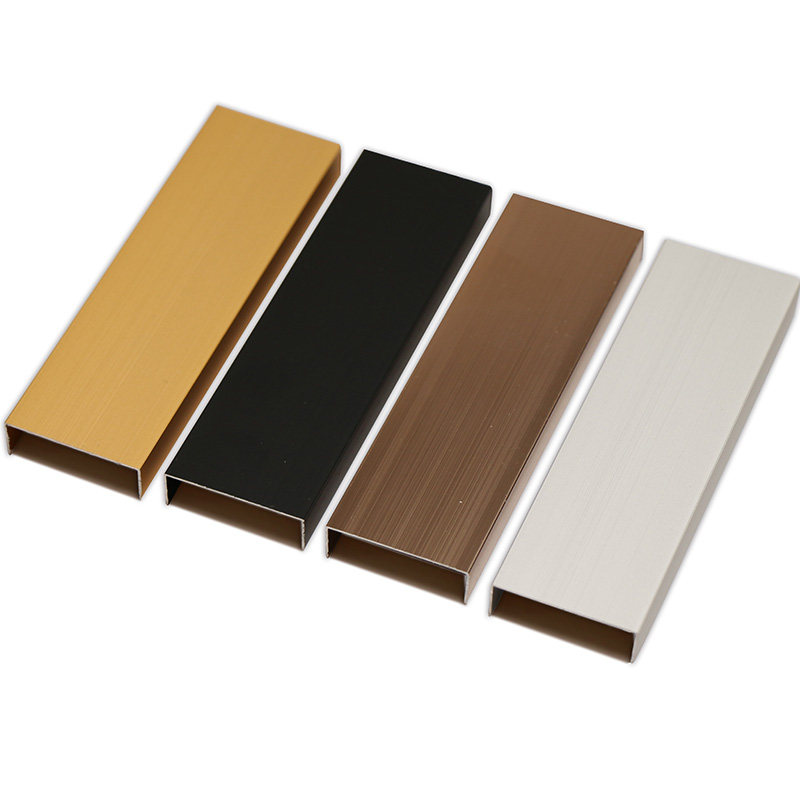

The aluminum alloy strip presents a host of advantages. In comparison to common metals, it weighs less, which facilitates effortless handling and installation. Moreover, through alloying and subsequent heat treatment, it can be rendered suitable for a wide array of applications. Secondly, it exhibits excellent corrosion resistance. A dense oxide film forms on its surface, effectively warding off the corrosive effects of moisture, acids, and alkalis, thereby guaranteeing a prolonged lifespan. Thirdly, its good plasticity renders it easily processable. Thanks to this property, it can be fabricated into various shapes and sizes via multiple manufacturing processes to cater to diverse requirements. Fourthly, it is both aesthetically pleasing and durable. The application of diverse surface treatment techniques endows it with rich colors and appealing decoration, while also imparting remarkable wear resistance and weatherability, minimizing the likelihood of fading. Finally, it is environmentally friendly and recyclable. Its recycling energy consumption is remarkably low, accounting for merely about 5% of that required for producing new aluminum, thus making a significant contribution to resource conservation. Additionally, it possesses favorable thermal and electrical conductivity, making it an ideal choice for applications such as radiators and electrical wires where these properties are essential.

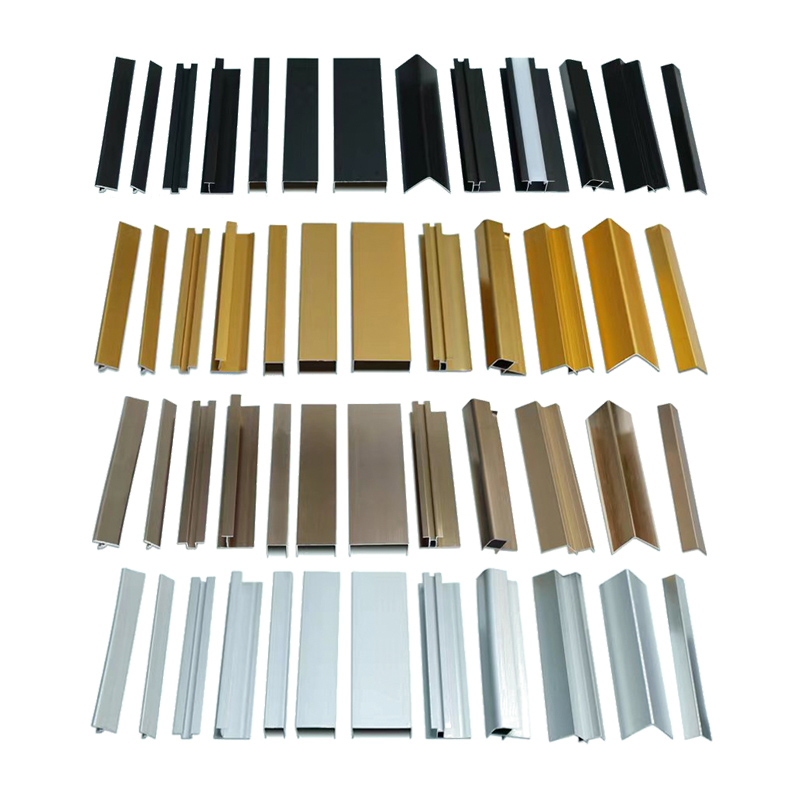

Definition:

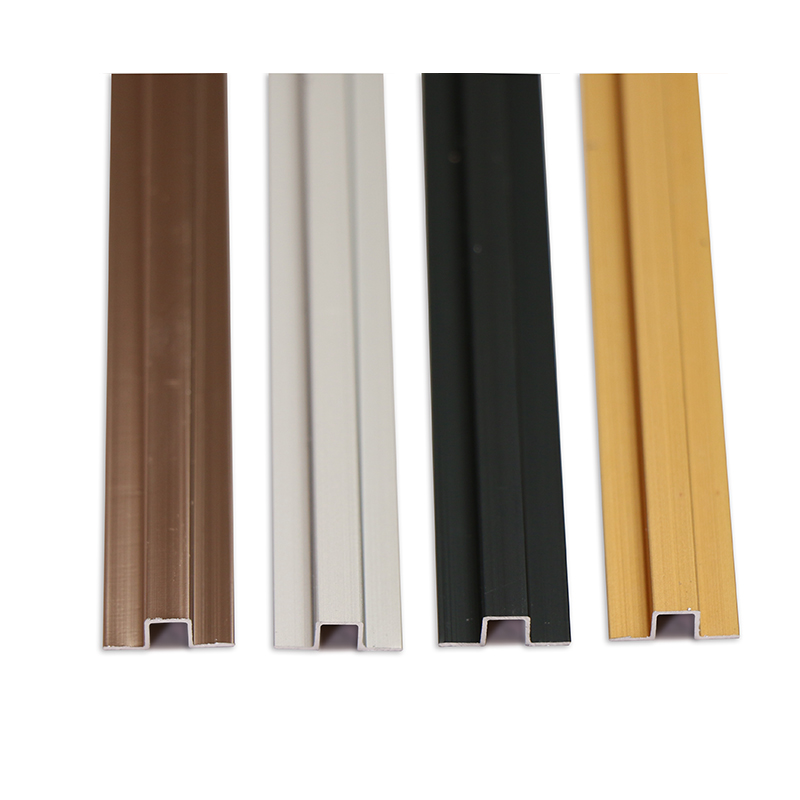

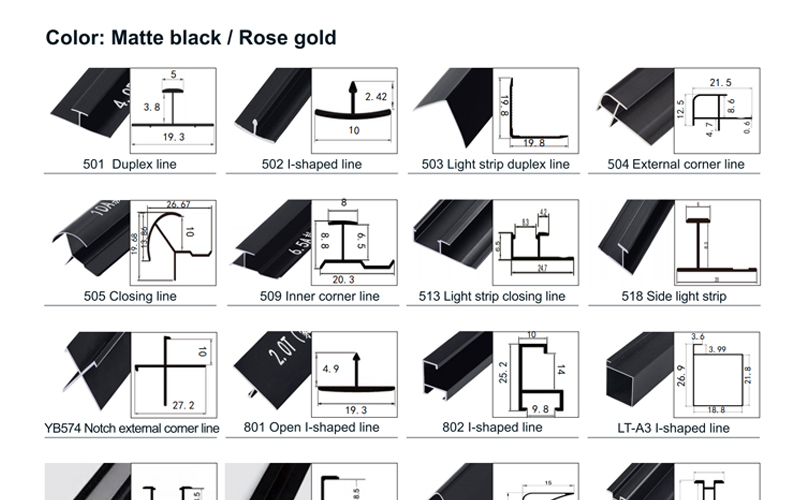

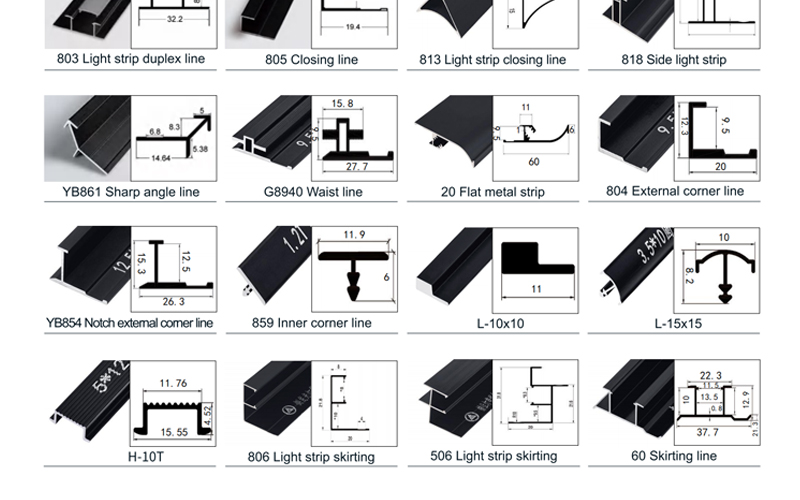

Wall panel closing strips, also known as closing strips or wrapping strips, are materials that cover and beautify the joints between wall or floor materials for the main purpose of alleviating the problem of abrupt corners.

Purpose:

It has the ability to connect two different materials, maintain the flat stability of building materials through the covering effect, which can cleverly cover the gap in the corner, play a beautiful decorative effect, and have practical functions. For example, in the wall decoration, the wall of different materials can be connected and transitioned naturally; On the floor materials such as wood flooring, floor tile edge treatment, laminate floor on both sides of the flat finish stability.

Product parameter

Application scenario:

The scope of application of the wall panel closing strip is quite wide, which is commonly seen in the following types of scenes:

Corner area: Whether it is the corner of the wall and the wall, or the corner formed by the connection between the ground and the wall, the closing strip can display its beautify effect, fine treatment of these areas, so that the original blunt corner line becomes smooth and natural, greatly improving the overall beauty of the space.

Yin and Yang corners and edge corners: In architectural decoration, Yin and Yang corners and all kinds of edge corners are often the visual focus, which is easy to be abrupt if handled improperly. The use of the wall panel closing strip can skillfully solve this problem, by fitting these special angles, to create a soft and delicate visual effect, making the decorative style of the entire space more unified and harmonious, thus enhancing the overall beauty.

Different material connection parts: In the wall decoration project, it is often encountered that the wall splicing of different materials, such as the stone wall and the wooden wall adjacent, or the tile wall and the latex paint wall. At this time, in order to ensure that the connection is both beautiful and firm, the wall panel closing strip becomes the only choice. It closely fits two different materials to fill gaps and achieve seamless transitions that highlight craftsmanship.

Edge treatment of floor materials: For floor materials such as wood floors and floor tiles, if their edges are not properly treated, they are prone to wear, warping and other problems, affecting the flatness and service life of the ground. Wall panel closing strip can solve this problem, when installed on the edge of the floor material, it is like putting on a layer of "protective clothing" to the floor, not only strengthen the stability of the flat decoration on both sides of the floor, effectively prevent edge deformation, but also add a delicate sense of ground decoration.

FAQ:

Appearance and durability

How is the surface color of the aluminum alloy metal strip formed?

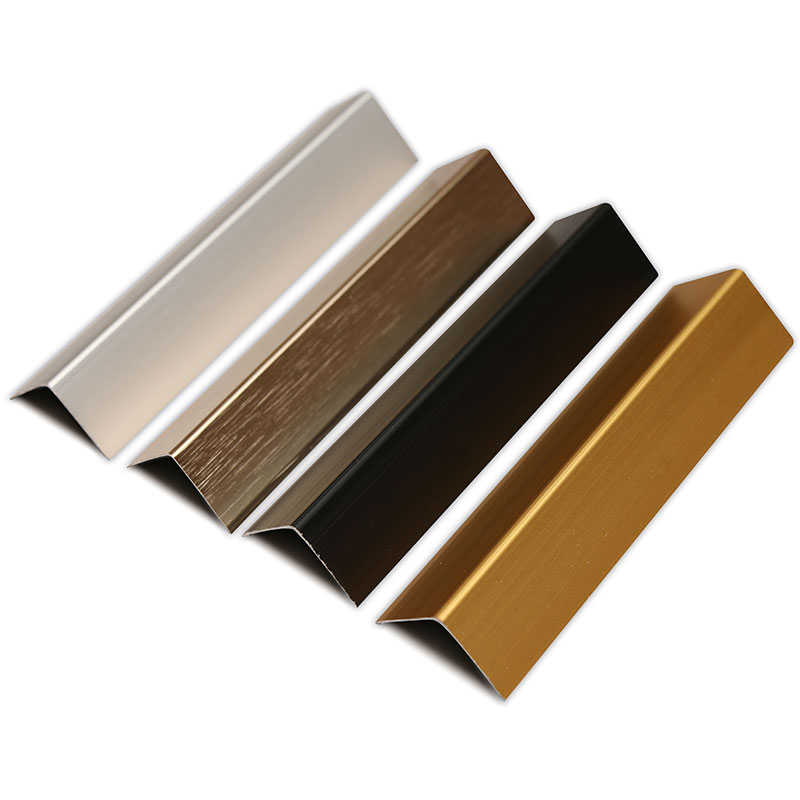

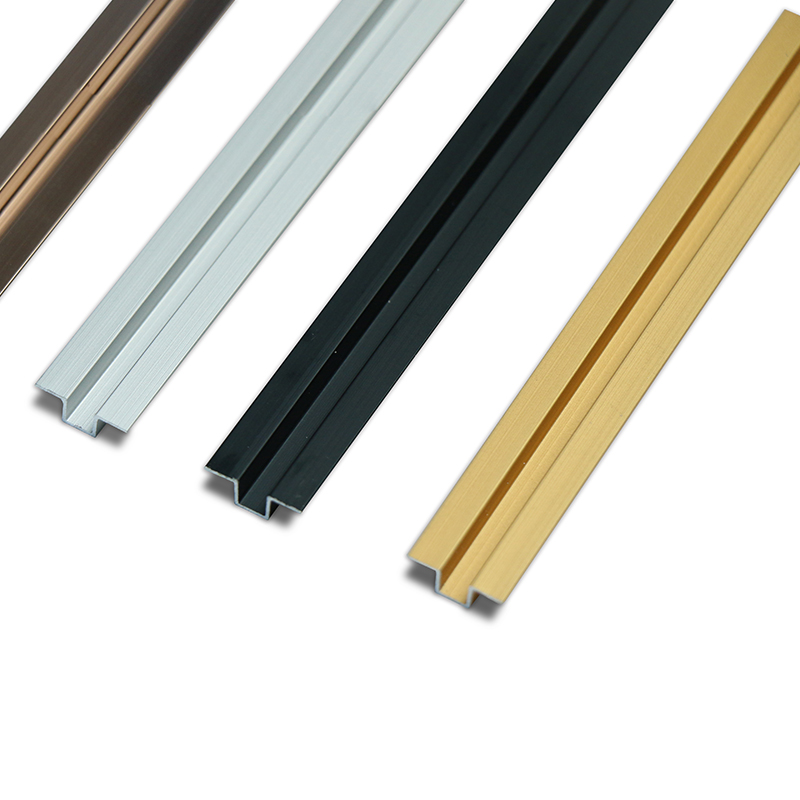

Through anodizing, electrophoretic coating, powder coating and other advanced technologies, it can present a rich variety of colors to meet different aesthetic needs.

How long can aluminum alloy metal strips be used outdoors without fading?

Because its surface is wear-resistant and weather-resistant, even if it is exposed to harsh environments such as outdoor strong light and wind and rain for a long time, it can maintain a bright appearance for a long time and is not easy to fade. However, the specific fading time will vary depending on the treatment process and environmental conditions, but in general, it can maintain good color for several years.

Environmental protection characteristics

Is aluminum alloy metal bar environmentally friendly?

It's environmentally friendly. With very high recyclability, the recycling energy consumption is only about 5% of the primary aluminum production energy consumption, greatly reducing the waste of resources, in line with the concept of sustainable development.

Can recycled aluminum alloy metal strips be used again to make metal strips?

Agreed. After a series of processes such as re-melting and processing, the recycled aluminum alloy can be made into aluminum alloy metal strips or other aluminum alloy products, and the quality is still reliable.