SPC Flooring: The Modern Choice for Global Projects

The Ultimate Guide to SPC Core Flooring: Revolutionizing Modern Interiors

Understanding SPC Core Flooring: A Market Overview

The global flooring industry is undergoing a significant transformation, driven by evolving consumer preferences and technological advancements. Among the most impactful innovations is SPC (Stone Plastic Composite) Core Flooring, a product category experiencing rapid growth in both residential and commercial sectors. As international B2B buyers seek durable, cost-effective, and aesthetically versatile solutions, SPC flooring emerges as a premier choice, combining resilience with design flexibility.

Market analysts indicate a sustained increase in demand for rigid core flooring, with SPC variants leading the segment. This surge is attributed to the material’s superior performance in diverse climates and high-traffic environments, making it a preferred option for hotels, retail spaces, offices, and multi-family housing projects worldwide.

Key Technological Advantages of SPC Construction

SPC Core Flooring is engineered with a multi-layer structure that delivers exceptional stability and longevity. The core of its innovation lies in the dense, mineral-based composite layer, primarily composed of limestone powder, polyvinyl chloride, and stabilizers. This composition results in a dimensionally stable plank that is highly resistant to indentation, moisture, and temperature fluctuations—a critical factor for international shipments and installations in varying climates.

Unlike traditional vinyl or laminate products, the rigid core of SPC flooring provides a solid underfoot feel and exceptional impact resistance. The manufacturing process involves high-pressure extrusion and precise calibration, ensuring uniform thickness and locking system integrity. The wear layer, typically consisting of a transparent UV-cured coating, protects against scratches, stains, and fading, while the decorative layer offers an extensive range of authentic wood, stone, and abstract visual designs.

Manufacturing Excellence and Quality Assurance

The production of high-grade SPC Core Flooring involves state-of-the-art technology and stringent quality control protocols. Raw materials undergo rigorous testing for purity and consistency before mixing. The composite mixture is then heated and formed under controlled pressure, creating a homogeneous core that is both dense and stable. Precision cutting tools ensure that each plank’s locking mechanism—usually a click-lock or fold-lock system—functions seamlessly for efficient, glue-free installation.

This meticulous manufacturing process not only guarantees product durability but also supports sustainable practices. Many premium SPC flooring lines utilize recycled materials and are themselves fully recyclable, appealing to eco-conscious buyers and projects seeking green building certifications.

Market Trends Driving SPC Flooring Adoption

Several key trends are influencing the global specification of SPC rigid core flooring. The demand for waterproof flooring solutions continues to rise, particularly in moisture-prone areas like kitchens, bathrooms, and basements. SPC’s 100% waterproof core addresses this need perfectly. Additionally, the growing preference for low-maintenance, hygienic surfaces in commercial and healthcare settings aligns with SPC’s non-porous, easy-to-clean characteristics.

Design trends also favor the wide range of visual options available in SPC collections, including realistic wood grain textures, large-format tiles, and intricate geometric patterns. The ability to provide these aesthetics with enhanced performance specs allows buyers to meet architectural design requirements without compromising on practicality.

Strategic Sourcing for International B2B Buyers

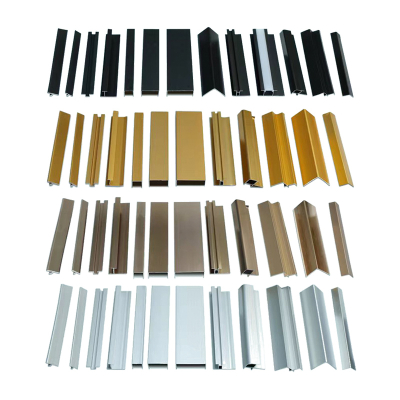

For wholesalers, distributors, and large project procurers, selecting the right SPC Core Flooring supplier involves evaluating technical specifications, compliance certifications, and logistical capabilities. Key parameters include thickness (ranging from 3mm to 8mm), wear layer thickness (directly affecting commercial durability ratings), and surface treatments (such as embossed-in-register textures for enhanced realism).

Leading manufacturers invest in international certifications like ISO, FloorScore, and CE markings, ensuring products meet global safety, emissions, and performance standards. Furthermore, robust packaging designed for intercontinental container shipping minimizes damage and loss, protecting buyers’ investments.

Frequently Asked Questions (FAQ)

Q1: What are the primary advantages of SPC Core Flooring over traditional vinyl planks or laminate?

SPC flooring offers superior dimensional stability and moisture resistance due to its rigid, mineral-based core. It does not expand or contract with temperature changes as significantly as laminate or traditional LVT, making it ideal for environments with fluctuating humidity or temperature. It is also generally more resistant to indentation from heavy furniture.

Q2: Is SPC flooring suitable for commercial high-traffic applications?

Yes, high-quality SPC Core Flooring with a sufficiently thick wear layer (typically 20 mil or above) is rated for heavy commercial use. It meets or exceeds standards for slip resistance, indentation recovery, and abrasion resistance required in retail spaces, offices, and schools.

Q3: What are the installation requirements for SPC rigid core flooring?

SPC flooring is designed for floating installation over a smooth, level subfloor. It can be installed over most existing surfaces, including concrete, plywood, and certain existing floorings. A vapor barrier is recommended in below-grade installations. The click-lock systems allow for tool-assisted DIY or professional installation without adhesives in most cases.

Q4: How does SPC flooring contribute to sustainable building practices?

Many SPC products are phthalate-free and have low VOC emissions, contributing to better indoor air quality. The durability and long lifespan reduce replacement frequency. An increasing number of manufacturers use recycled content in the core and offer recyclable products at end-of-life, supporting circular economy principles.

Navigating Your SPC Flooring Procurement

The decision to incorporate SPC Core Flooring into your supply portfolio or project plan requires partnering with a knowledgeable and reliable manufacturer. Focus on suppliers who demonstrate a commitment to consistent quality, comprehensive technical support, and a deep understanding of international market requirements.

Ready to elevate your flooring offerings with high-performance SPC solutions? We invite you to connect with our expert team for detailed technical specifications, compliance documentation, and tailored commercial proposals. Discover how our advanced SPC Core Flooring collections can meet your specific market demands and project requirements, providing the durability, style, and value your clients expect. Contact us today to initiate a professional consultation.