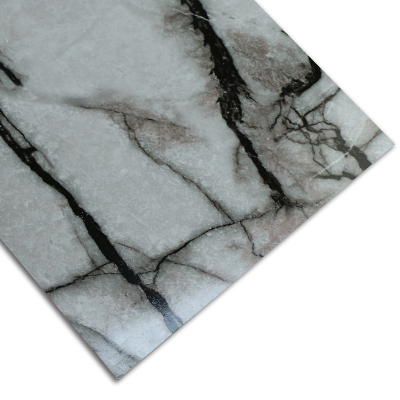

How Scratch-Resistant Is Engineered Flooring?

Engineered Hardwood: The Global B2B Buyer's Guide to Premium, Sustainable Flooring Solutions

Market Overview: Why Engineered Hardwood is the Global Mainstream Choice

The global market for premium flooring is undergoing a profound transformation. Positioned between solid wood and laminate, engineered hardwood flooring has emerged as the leading choice for international commercial projects and high-end residential builds, thanks to its superior performance balance. This shift is driven by B2B buyers—importers, distributors, project developers, and architects—who demand products that combine aesthetic appeal, technical resilience, and supply chain efficiency.

According to recent analysis by Grand View Research, the global engineered wood flooring market was valued at USD 46.2 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by rapid urbanization, a resurgence in commercial construction, and an unwavering global preference for authentic wood aesthetics paired with modern practicality. For the discerning B2B buyer, understanding the nuances of this product category is no longer optional; it is essential for competitive sourcing and project success.

Technical Deep Dive: The Anatomy of Superior Performance

The core advantage of engineered hardwood lies in its sophisticated, cross-ply construction. Unlike solid wood, which is a single piece susceptible to environmental changes, engineered boards are designed for dimensional stability in variable climates.

Multi-Layer Construction: The Foundation of Stability

A typical high-grade engineered wood floorboard consists of three to nine layers bonded perpendicularly. This structure counteracts wood’s natural tendency to expand and contract.

Wear Layer (Top Veneer): This is the actual layer of premium hardwood (e.g., oak, walnut, maple), with thickness ranging from 2mm to 6mm. A thicker wear layer allows for multiple sanding and refinishing over the lifetime of the floor, directly impacting its longevity and value proposition for long-term commercial flooring projects.

Core Layer(s): Made from plywood or HDF (High-Density Fiberboard), this core provides the structural backbone. Plywood cores offer superior strength and moisture resilience, while HDF cores deliver a perfectly flat, stable substrate.

Balancing Back Layer: This bottom ply ensures the board remains flat and prevents cupping.

Advanced Finishes & Installation

Modern manufacturing has revolutionized surface durability and installation ease.

Surface Finish Technologies: UV-cured finishes with aluminum oxide or ceramic bead additives create an exceptionally hard, scratch-resistant surface, ideal for high-traffic commercial flooring. Low-VOC, matte oil finishes are also trending, offering a natural look and easy spot-repairs.

Click-Lock Systems: The widespread adoption of unilin or valinge locking systems enables a fast, glue-less, and floating installation. This significantly reduces labor time and costs, a critical factor for large-scale B2B procurement and project timelines.

Key Market Trends Shaping B2B Procurement in 2024

To source effectively, buyers must navigate these dominant trends in the engineered hardwood sector:

Demand for Longer, Wider Formats: The architectural trend favors wide plank engineered hardwood (over 7 inches) and extra-long lengths. These formats minimize seams, create a sense of spaciousness, and align with contemporary design aesthetics.

The Rise of Matte & Natural Finishes: High-gloss is receding in favor of matte, wire-brushed, and oiled finishes. These low-sheen hardwood surfaces offer a sophisticated, contemporary look while better concealing footprints and minor wear.

Sustainability as a Non-Negotiable: B2B buyers increasingly require full-chain transparency. Certifications like FSC (Forest Stewardship Council) or PEFC are now standard expectations. Additionally, products using low-VOC adhesives and finishes contribute to healthier indoor air quality, a key factor for projects targeting LEED or WELL building standards.

Growth in AC4-AC6 Rated Products: For commercial applications, demand is soaring for boards with high Abrasion Class (AC) ratings (AC4, AC5, AC6). These heavy-duty engineered wood floors guarantee performance in retail, office, and hospitality settings.

The Manufacturing & Application Process: A Brief Overview

Understanding the journey from raw material to finished installation builds confidence in the product's quality.

Manufacturing: The process begins with sourcing dried, sustainable hardwood for the veneer. This veneer is precision-sliced and adhered to the cross-stacked core layers under high heat and pressure. The board is then milled to precise tolerances, with the locking profile cut. Finally, it undergoes sanding, staining (if applicable), and the application of multiple protective finish coats, often cured by UV light.

Application: For end-users, installing engineered hardwood floors is straightforward. After proper subfloor acclimatization and preparation, the click-lock boards are interconnected across the room, typically without glue (floating floor method). This system allows for quick installation over various subfloors like concrete, plywood, or existing flooring, making it a versatile solution for renovation and new construction alike.

FAQ: Addressing Common B2B Buyer Questions

Q1: What is the primary advantage of engineered hardwood over solid hardwood for international trade?

A1: The key advantage is superior dimensional stability. Its cross-ply construction makes it highly resistant to warping and gapping caused by fluctuations in humidity and temperature during transit and in different climatic zones. This allows for reliable installation over concrete slabs and with underfloor heating systems, which are common globally, minimizing post-installation complaints.

Q2: How do I assess the quality and longevity of different engineered hardwood products?

A2: Focus on three technical specifications: 1) Wear Layer Thickness: A 4mm+ veneer allows for several refinishes. 2) Core Material: Multilayer plywood cores generally offer better structural integrity and moisture resistance than HDF. 3) Finish AC Rating: For commercial use, specify AC4 (general commercial) or AC5/AC6 (heavy commercial). Always request samples and technical data sheets.

Q3: Are there sustainable options available, and what certifications should I look for?

A3: Absolutely. Sustainable engineered hardwood is a major selling point. Look for products certified by the Forest Stewardship Council (FSC) or the Programme for the Endorsement of Forest Certification (PEFC). These ensure wood is from responsibly managed forests. Additionally, inquire about low-VOC or formaldehyde-free adhesives (e.g., meeting CARB ATCM Phase 2 or E1/E0 standards).

Q4: Is engineered hardwood suitable for all commercial environments?

A4: While highly versatile, selection must match the environment. For standard offices, retail, and hospitality areas, AC4 or AC5 rated engineered hardwood is excellent. For ultra-high-traffic areas like airport terminals or main retail concourses, an AC6 rating or alternative flooring might be recommended. Always consult with the manufacturer for specific project suitability.

Professional Call to Action for Global Buyers

The engineered hardwood market presents a significant opportunity for B2B buyers to meet evolving global demand with a technically superior and aesthetically versatile product. To make informed, profitable sourcing decisions, due diligence is key.

Ready to elevate your flooring portfolio? We encourage you to take the next step:

Request a comprehensive catalog and full technical specification sheets for our latest commercial-grade engineered wood flooring collections.

Schedule a dedicated consultation with our technical team to discuss the specific requirements of your upcoming project or market.

Order sample boxes to personally evaluate the finish quality, locking system, and color accuracy of our premium engineered hardwood solutions.

Contact our international sales team today to discuss how our certified, high-performance flooring can become a cornerstone of your commercial and high-end residential offerings. Let's build lasting partnerships on a solid foundation.