How Do You Clean Engineered Timber Floors

The Ultimate Guide to Professional Cleaning and Maintenance of Engineered Wood Flooring: Based on International Standards

Engineered wood flooring, with its outstanding stability, aesthetic appeal and relatively affordable price, has become a widely popular floor decoration material worldwide. However, its long-term beauty and lifespan largely depend on scientific and continuous cleaning and maintenance. Incorrect cleaning methods not only damage its surface but may also cause irreversible physical damage and render the original factory warranty invalid. This guide will combine the suggestions of the North American Wood Flooring Association (NWFA), top European flooring manufacturers and professional Australian installers to provide you with a complete and professional care plan.

Chapter One: Understanding Your Engineered Wood Flooring - The Foundation of Proper Care

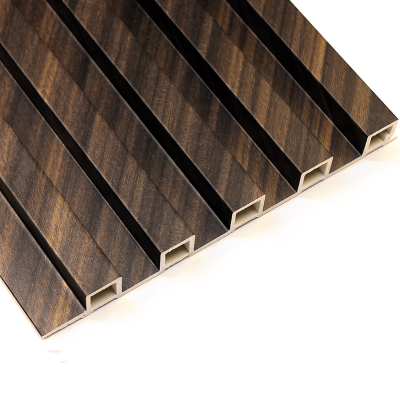

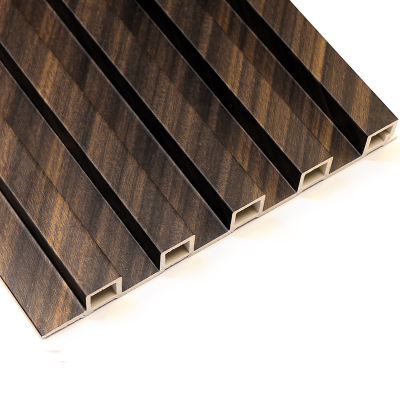

Before you begin cleaning, it's essential to understand what you're caring for. Engineered wood flooring is constructed by fusing multiple layers of wood together. Its surface features a solid wood wear layer, which is protected by a durable coating. The primary goal of cleaning is to maintain this protective layer, not the wood beneath it.

1.1 Identify your coating type

The vast majority of modern engineered wood floors use surface sealing coatings, such as:

Polyurethane/acrylic urethane: The most common, providing excellent wear resistance and water resistance.

Aluminum oxide: Extremely hard and durable, often used in high-end products.

Uv-cured coating: A coating that cures under ultraviolet light, which is very strong and environmentally friendly.

Identification method: Drop a few drops of water on the floor. If the water droplets remain spherical and do not seep in, and leave no trace when wiped off after a few minutes, then your floor is a surface sealing coating. This is the most common situation.

A few floors are coated with penetrating oil-based or hard wax oil. This coating will penetrate into the interior of the wood fibers, creating an open, matte and natural-textured effect.

Identification method: The water droplet will be absorbed in a short time and leave a dark watermark at that location.

This guide mainly focuses on the surface-sealed coating floors that dominate the market, but it will particularly note the care methods for oily floors.

1.2 Three Core Principles of Cleanliness:

Professional care is based on three unshakable principles:

Principle One: Prevention is better than cure. 80% of floor wear and tear is caused by daily dust and sand particles, which rub against the coating like sandpaper.

Principle Two: Moisture is the greatest enemy. Any form of water accumulation may seep into the seams, causing the edges of the wooden boards to warp, delaminate and deform.

Principle Three: Compatibility of chemicals. The wrong cleaning agent can chemically degrade the coating, causing it to become dull, sticky and even peel off.

Chapter Two: The Complete Process of Daily and Periodic Cleaning

A professional cleaning process should be divided into three levels: daily, weekly and deep cleaning.

2.1 First Layer of Defense: Daily dry cleaning (daily or every two days)

Objective: To remove abrasive dry particulate matter.

Tool:

Soft-bristled brooms or electrostatic dusting mops: Quick and effective, they can easily collect dust and hair.

Vacuum cleaner: It must be equipped with a dedicated suction head or setting for hard floors and ensure that the roller brush is turned off. High-speed rotating roller brushes (especially those already entangled with sand grains) can cause significant microscopic scratches on the floor surface.

2.2 Second Layer of Defense: Regular moist cleaning (weekly or as needed)

This is the most crucial and error-prone part. "Slightly moist" is the key word throughout the entire process.

Professional tool preparation

High-quality microfiber flat mop. Superfine fibers can effectively grasp and lock in dirt instead of pushing it around.

A spray bottle (optional, but recommended for controlling water volume).

A special floor cleaner with neutral pH, free of soap bases, ammonia water and wax.

Two buckets (if the two-bucket method is used, this is the best practice).

Professional eight-step cleaning method

Thorough dry suction/sweeping: This is a mandatory prerequisite step to ensure that all sand particles have been removed.

Prepare the cleaning solution correctly: Dilute it with warm water strictly in accordance with the proportion indicated on the cleaning agent bottle. Warm water can dissolve stains better, but never use hot water.

Adopt the "two-bucket method" : one bucket holds the cleaning solution, and the other bucket holds clean water for rinsing the mop. This can prevent sewage from being repeatedly brought onto the floor.

Wring Thoroughly: Soak mop, then wring (by hand/towel/built-in device) until very damp but not dripping. Crucial for preventing water seepage.

Follow the Grain: Wipe along planks, not across. Blends streaks with grain and cleans gaps better.

Rinse Often: Every few square meters, rinse mop in clean water, wring, and reapply solution.

Spot Clean Stains: For sticky spots, spray cleaner, wait one minute, then wipe with wrung mop/cloth.

Final Dry Pass: (Optional) In humid conditions or if over-wet, quickly use a dry microfiber cloth to prevent water marks.

Chapter Three: Professional Selection of Products and Tools

3.1 Selection of Cleaning Agents:

Recommendation: Look for products clearly labeled "for sealed hardwood floors", "pH neutral", "no-wax", "no-soap". Well-known brands such as Bona (USA), Bruce (USA), Fila (Italy), etc. are all professional-level choices.

Absolutely prohibited

Vinegar/lemon juice: Its acidity will corrode and passivate the luster of the floor coating over a long period of time.

Soap base/general-purpose cleaner: It leaves sticky residues, adsorbs dust, and makes the floor dirty and dull more quickly.

Ammonia water: It can degrade polyurethane coatings.

Any form of steam mop: High-temperature steam is the "number one killer" of engineered wood flooring. It can penetrate tiny seams, damage laminating adhesives, cause permanent warping and delamination, and usually render the warranty invalid.

Wax or polish: Unless your floor has an oily finish and the product is recommended by the manufacturer, using wax on a sealed floor can cause a slippery accumulation that will require professional sanding to remove in the future.

3.2 Tool Selection:

The flat microfiber mop is the gold standard.

Cloth: Only use microfiber cloth or 100% cotton soft cloth.

Chapter Four: Handling Special Situations and Advanced Care

4.1 Emergency spills handling:

Immediately dry it with a soft and absorbent cloth or paper towel. For sticky substances, you can gently wipe them with a cloth dipped in a special floor cleaner.

4.2 Stubborn Stain Treatment:

Oily substances (lipstick, asphalt) : Use a cloth dipped in a small amount of detergent to gently wipe.

Chewing gum, wax, glue: Harden them with ice packs or plastic ice cubes, and then gently scrape them off with a plastic scraper (do not use metal). Clean the remaining part with a cleaner.

Black heel marks: They can usually be wiped off with a special cleaner and a soft cloth. If it is ineffective, you can slightly dip a little isopropyl alcohol and wipe it, and immediately follow up with a damp cloth.

4.3 Deep Cleaning and luster restoration:

Even with proper care, the glossiness of high-traffic areas will decline over time. If the floor structure is intact but the surface is dull, you may consider:

Professional repair and care: Contact a professional for a light "screening" (slight sanding) and repainting the topcoat, which can make the floor look brand new.

Use the "rejuvenating agent" approved by the manufacturer: Some brands offer rejuvenating products that do not require sanding and can form a new protective film on the old coating, restoring luster and protection.

Chapter Five: Special Instructions for Oily/Hard Wax Oil Floors

If your floor has an oily surface treatment, the philosophy of care is completely different:

Cleaning: Soap and detergent specially designed for oily floors must be used. These cleaning agents usually contain a small amount of soap components, which can replenish oil while cleaning.

Maintenance: Maintenance oil or refresher should be used regularly (usually every 1-2 years, depending on the degree of wear). This process involves cleaning, light sanding (sometimes necessary), oiling and polishing to repair worn areas and rebuild the protective layer.

Conclusion

Professional cleaning of engineered wooden floors is not a cumbersome task but rather the cultivation of a series of scientific habits. It requires you to abandon the notion of "the more, the better" in cleaning and instead embrace "just right" precise care. By adhering to the core strategy of daily dust prevention, micro-moisture cleaning, and eliminating incorrect chemicals and vapors, your engineered wood flooring will not only maintain its fresh luster throughout the year but also have a lifespan far exceeding expectations, making it a lasting and beautiful investment in your home. Always keep in mind: The warranty and care guidelines provided by your floor manufacturer are the highest authority you should follow.