How would you define laminate flooring?

What is laminate flooring? -- An Engineering Model of Modern Floor Materials

Laminate flooring, professionally known as "laminated flooring," is a type of multi-layer composite flooring synthesized through high-tech processes. Its essence is a floor made of four or more layers of materials with different functions, permanently bonded together under high temperature and high pressure to imitate natural materials. Its birth and development represent the successful innovation of traditional materials by industrial design. The core objective is to retain the aesthetic appeal of natural materials like wood and stone while overcoming their limitations in durability, stability, and Laminate Cost, thereby meeting the demands of modern high-intensity, fast-paced life and commercial spaces.

The Core Value and Characteristics of Laminate Flooring

1.Outstanding Durability and Wear Resistance: This is its most notable advantage. The special wear-resistant layer on the surface effectively resists scratches, impacts, stains, and UV radiation. Its wear resistance is quantified by the AC grade (Abrasion Class), ranging from AC3 for home bedrooms to AC6 for heavy commercial traffic, providing a scientific basis for selection. This durability is a key factor in the long-term value and overall Laminate Price proposition.

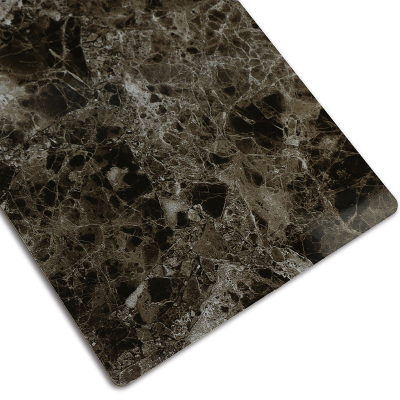

2.Infinite Decorative Diversity: The decorative layer uses high-precision printing technology to realistically imitate any wood grain, stone vein, tile joint, or abstract art pattern. This makes it a favorite among interior designers, capable of seamlessly integrating into any style. The vast range of Laminate Floor Colours and patterns ensures there is an option for every design vision, from classic oak to contemporary grey tones, all achievable without the high Laminate Cost of natural materials.

3.Outstanding Dimensional Stability: The high-density core base material has a low moisture absorption rate, making it less prone to expansion and contraction compared to solid wood. This makes it suitable for kitchens and basements and compatible with floor heating systems (a dedicated model must be selected). Proper preparation of the subfloor Under Laminate Flooring is crucial to maximize this stability.

4.Convenient Installation and Maintenance: Modern laminate flooring generally uses an advanced locking system, allowing panels to "click" together for a floating installation without glue. This shortens construction time and lowers the installation threshold. The dense, smooth surface makes daily cleaning simple. The condition of the subfloor Under Laminate Flooring must be level and dry to ensure the locking system performs optimally. Renowned systems like those from Quick Step Floor are engineered for seamless and secure installation.

5.Environmental Protection and Sustainability: The main raw materials are fibers from fast-growing wood or industrial wood residues, with low consumption of rare natural resources. Products meeting standards like the European EPD are strictly controlled for formaldehyde emissions. While the initial Laminate Price is attractive, its long lifespan and sustainable sourcing contribute to its eco-friendly profile.

How is laminate flooring manufactured? -- Comprehensive Analysis of Precision Lamination Process

The manufacturing process is a blend of materials science and precision engineering, ensuring high product consistency.

Act One: Forging of the Core Substrate - High-Density Fiberboard (HDF)

The "backbone" of the floor is HDF, whose quality determines stability, impact resistance, and interlocking strength.

1.Wood Preparation: Uses wood residues from fast-growing softwoods (e.g., pine, spruce), crushed into fibers.

2.Resin Mixing and Laying: Fibers are mixed with synthetic resins (e.g., melamine-formaldehyde) and formed into a continuous, uniform mat.

3.Hot Pressing: The mat is pressed at over 200°C under high pressure, forming HDF boards with a density typically no less than 850kg/m³. This high density is crucial for lock integrity and is a key quality differentiator reflected in the Laminate Price of premium products like Quick Step Floor.

Act Two: Precise Superposition of Functional Layers - Four-Layer Structure

This step endows the floor with its soul and body. The structure from bottom to top is:

1.Balance Layer (Backsheet): Impregnated paper that provides stress balance and a moisture barrier from the subfloor Under Laminate Flooring.

2.Core Layer (Substrate): The HDF board, providing structural strength, rigidity, and housing the lock system.

3.Decorative Layer: High-definition printed paper impregnated with resin, which determines the final appearance and the vast array of available Laminate Floor Colours.

4.Wear-Resistant Layer: A transparent layer containing hard Aluminum Oxide particles, providing armor-like protection and determining the AC rating.

Act Three: Fusion and Solidification - High-Pressure Lamination (HPL)

The stacked layers are fused into a single, dense whole under high temperature (200-250°C) and pressure in a continuous press—this is the "lamination" process. The board is then cooled and cured to ensure long-term stability.

Act Four: Giving Form and Touch - Fine Processing and Lock Forming

1.Cutting: The continuous panel is cut into standard-sized floorboards.

2.Lock Milling: High-precision CNC milling machines carve the locking structures on the edges. High-quality locks, such as those from Quick Step Floor, allow for glue-free, self-tightening, and secure installations, which can influence the final installed Laminate Cost by reducing labor time.

3.Surface Texture Treatment (Synchronous Embossing): High-end laminate uses embossing to create a surface texture that matches the decorative layer, enhancing the realistic feel of wood or stone Laminate Floor Colours and patterns.

Act Five: Ultimate Quality Inspection and Packaging

Every floor is inspected for color differences, surface defects, and dimensional tolerances. Lock fit is tested. Qualified products are packaged with information on AC grade, moisture-proof grade, and formaldehyde emission level. This rigorous quality control, consistent with brands like Quick Step Floor, ensures the product meets its promised performance, justifying its Laminate Price and ensuring customer satisfaction.

Summary

Laminate flooring is an outstanding industrial achievement that integrates creativity, chemistry, physics, and mechanical engineering. Through precise layered structure and rigorous manufacturing, it achieves an outstanding balance in durability, aesthetic diversity (offering countless Laminate Floor Colours), stability (dependent on proper subfloor Under Laminate Flooring), and economy. While the initial Laminate Price is a key advantage, the long-term Laminate Cost of ownership is favorable due to its durability and low maintenance. It is a rational choice for modern spaces and represents continuous innovation in material application and sustainable development, with brands like Quick Step Floor often leading the way in technology and design.