Does mold grow under vinyl plank flooring?

Latent home health risks: The truth behind mold growth under Vinyl baseboards

In modern home decoration, Vinyl Plank Flooring, with its excellent waterproof performance, easy installation and maintenance features, has become the first choice for more and more families and commercial Spaces. However, behind this seemingly perfect floor material lies a health hazard that is easily overlooked - the problem of mold growth beneath the floor. This article will delve into the causes, hazards and prevention measures of this phenomenon from an international professional perspective.

I. The Scientific Basis of Mold Growth

To understand why mold can grow under vinyl baseboards, it is first necessary to know the four basic conditions for mold growth: nutrient sources, moisture, suitable temperature and oxygen. These conditions can precisely be met under the vinyl base plate in a specific environment.

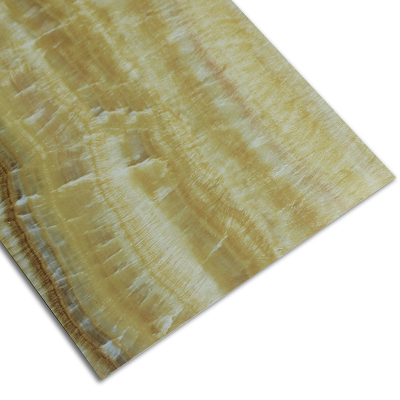

Although the base material of ethylene is made of inorganic materials such as polyvinyl chloride (PVC) and stone powder (calcium carbonate), and does not directly provide nutrients for mold, the base material beneath it becomes a "breeding ground" for mold. Wooden base layers (such as plywood or OSB boards), traditional organic bedding layers (such as cork or regenerated cellulose bedding), and even the dust and organic matter deposited on the surface of concrete base layers can all provide sufficient nutrients for mold.

Moisture is the key factor causing mold problems. The sources are diverse: pipe leakage, ground overflow, water vapor penetration from the concrete base, condensation in the air, or insufficient drying of the base during construction, etc. It is particularly worth noting that the waterproof property of the vinyl base board becomes a "double-edged sword" in this situation - it can effectively prevent liquids from seeping in from the surface, but it also makes it difficult for moisture that enters the floor from other sources to evaporate, creating a continuously damp and sealed environment.

Ii. Risk Analysis from an International Professional Perspective

According to the standards of the American Society for Testing and Materials (ASTM), a strict moisture test must be conducted on the base layer before installing the vinyl base plate. For concrete base layers, the relative humidity probe test method (ASTM F2170) should be used to ensure that the internal relative humidity of the base layer is lower than the threshold specified by the manufacturer (typically 75%-80%). For wooden base layers, a needle moisture meter should be used for detection to ensure that the moisture content does not exceed 12%.

Research by the European Institute of Building Science shows that in humid climates, the problem of condensation under the floor is particularly prominent. When warm and humid air seeps into the colder underfloor through seams or edges, condensation water is produced, creating ideal conditions for mold growth.

Experts from the Japan Society for Interior Environment further pointed out that if the concrete base in new buildings does not dry for a sufficient period of time (usually 60 to 90 days), it will continuously release moisture after the installation of the floor, leading to long-term dampness problems.

Iii. The Severity of Mold Hazards

The mold growing beneath the floor not only damages the building structure, but more importantly, it poses a threat to the health of the occupants. The spores and metabolic products released by mold may cause allergic reactions, respiratory diseases, and even more serious health problems. The United States Environmental Protection Agency (EPA) has listed indoor mold contamination as one of the significant public environmental health issues.

What is even more troublesome is that due to the sealing characteristics of vinyl base plates, these problems are often difficult to detect before they cause significant damage. By the time the floor warps, stains appear at the joints, or a musty smell develops, the problem is usually quite serious.

Iv. Professional Prevention and Control and Solutions

From the perspective of international practice, prevention is far better than governance. First of all, strict base preparation and moisture testing must be carried out before installation. Secondly, the appropriate moisture-proof layer should be selected based on the type of base layer: for concrete base layers, at least 0.15 millimeters thick polyethylene film should be laid, and the joints should be overlapped and sealed. For wooden base layers, it is necessary to ensure they are fully dry and select an appropriate anti-mold bedding layer.

In terms of material selection, experts recommend using inorganic anti-mold layers, such as high-density extruded polystyrene (XPS) or electronically cross-linked polyethylene (IXPE) foam. At the same time, maintaining the indoor relative humidity between 30% and 50% can effectively reduce the risk of mold growth.

Once mold problems are detected, a professional repair process should be followed: First, conduct a comprehensive environmental assessment, including air sampling and surface sampling; Secondly, thoroughly fix the water source problem; Then, professional personnel will carry out the dismantling, cleaning and repair work, including negative pressure isolation using HEPA filtration equipment and professional treatment of contaminated materials, etc.

V. Industry Development Trends and Technological Innovation

Facing this challenge, the flooring industry is actively seeking technological breakthroughs. Some leading manufacturers have begun to introduce "smart" floor systems that monitor the environmental conditions beneath the floor in real time through embedded sensors. Meanwhile, the new "breathing" floor system, while maintaining its waterproof performance, allows water vapor to escape through specific channels, effectively reducing the risk of dampness.

The International Organization for Standardization is also considering incorporating stricter moisture management requirements into global building codes and establishing a full-chain responsibility system covering production, installation and maintenance.

Vi. Consumer Guide

For consumers, it is crucial to choose a reputable installer and ensure that they follow international standards for base preparation and moisture testing. At the same time, floor and bedding products that have passed international anti-mold certification should be selected. In daily use, it is necessary to pay attention to timely cleaning up unexpected spills, regularly check the changes in floor joints and the condition of edges, and be vigilant for the appearance of unknown odors.

Conclusion

The problem of mold growth under vinyl base plates is a complex subject involving materials science, building physics and microbiology. While enjoying the convenience brought by modern materials, we need to pay more attention to their potential risks, follow professional norms and prevent problems from occurring at the source. Only through the joint efforts of consumers, installers and manufacturers can we ensure that our living environment is both beautiful and healthy.

As a senior architectural scientist put it, "The best mold control is prevention." A little more caution before installation is far better than paying ten times the cost and health price after discovering problems. Let's adopt a scientific attitude and professional knowledge to create a safe and healthy living environment for ourselves and our families.