What constitutes laminate flooring, and how is it manufactured?

Laminate flooring: A comprehensive guide to its composition and manufacturing

1.Definition and Core concepts

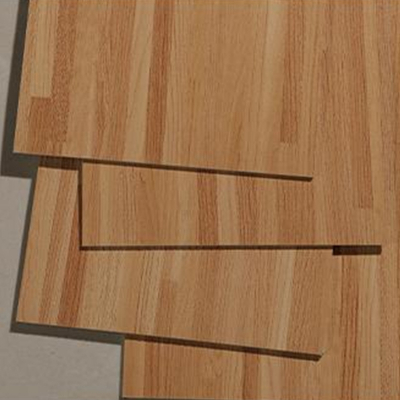

In simple terms, Lamato is a multi-layer synthetic flooring product that is fused together through a high-pressure manufacturing process, aiming to imitate the appearance of natural materials such as wood or stone. Its invention was first created by the Swedish company Perstorp in 1977 and later commercialized as Pergo. By offering highly durable, cost-effective, aesthetically pleasing and diverse alternatives to traditional hardwood and stone, it revolutionized the flooring industry.

The fundamental principle of laminate flooring lies in the separation of functions. Unlike solid wood flooring (where a single material needs to simultaneously undertake the dual responsibilities of an aesthetically pleasing surface and structural support), laminate flooring precisely allocates different functions to different professional layers. The top layer is dedicated to wear resistance, the decorative layer is responsible for aesthetics, and the core layer provides stability and structural support. This collaborative design with each party performing its own duties is the key to its outstanding performance and global popularity.

From a more macroscopic industrial perspective, the birth and development of laminate flooring represent the efficient utilization of resources and the successful simulation of natural materials in industrial production. It enables the precious wood grain or rare stone texture to enter ordinary households and various commercial Spaces at more affordable prices, with more stable performance and more convenient installation methods, meeting the comprehensive demands of the modern consumer market for aesthetics, practicality and sustainability.

2. Dissection of laminates: layer-by-layer decomposition

Laminate flooring is a complex sandwich, usually composed of four layers, each with a key function.

Coating (wear layer) :

This is a transparent and durable topcoat that can protect the floor from daily abuse. It is mainly composed of aluminium oxide (Al₂O₃), which is an exceptionally hard mineral compound. This layer is integrated with the decorative layer beneath through the manufacturing process.

Function: Scratch-resistant, wear-resistant, stain-resistant, and UV-fading.

Measurement: Its durability is quantified by its wear grade (AC) rating, which is an international standard (EN 13329) ranging from AC1 (medium residential) to AC5 (heavy commercial). For instance, AC3 is applicable to all residential rooms and light commercial areas, while AC5 is suitable for department stores and public buildings.

Decorative layer:

This is high-resolution photo paper, which makes the floor visually appealing. Its printing details are extremely meticulous to replicate the texture of oak, marble or concrete.

Function: Provide an aesthetically pleasing appearance for the floor.

Quality difference: The quality of this kind of printed matter is of vital importance. High-end laminates use higher-resolution printed materials and employ techniques such as embossing to create textures that match the textured patterns (a feature known as registered embossing), significantly enhancing the sense of reality.

Core Layer (Substrate) :

This is the thickest and most structurally crucial layer. Historically, it was made of high-density fiberboard (HDF), but medium-density fiberboard (MDF) was also used. HDF is a superior, denser and more moisture-proof option.

Composition: HDF is formed by fusing wood fibers (typically from fast-growing sustainable species or recycled wood waste) with synthetic resins under heat and pressure.

Function: Provides dimensional stability, impact resistance, structural strength and click locking mechanism. The density of the HDF core is a key indicator of quality, directly affecting the board's ability to resist indentation and maintain the safety of the locking system.

Backing layer (Stabilizer) :

This is a melamine-impregnated or polymer-based thin sheet laminated at the bottom of the core.

Function: Provides a moisture-proof barrier and prevents the board from warping by balancing the stress from the top layer. It also enhances the overall structural stability of the wooden board.

Additional component: Moisture-proof layer (optional but common)

Many modern laminates have comprehensive moisture-proof functions. This is not a single layer, but rather the processing of the core material and its edges. It includes:

Wax or resin impregnation: HDF cores are treated with hydrophobic materials.

Sealing edge: During the manufacturing process, apply waterproof sealant along the click-lock contour. This is of vital importance because if liquid seeps into the coal seam, the core is very vulnerable to water damage.

3. Manufacturing Process: A precise symphony of pressure and heat

The production of laminate flooring is a highly automated and continuous process, mainly employing two core technologies: direct pressure lamination (DPL) and high-pressure lamination (HPL).

A. Direct Pressure Lamination (DPL) - The mainstream manufacturing process

More than 90% of household laminate flooring is manufactured using the DPL process. This process is highly efficient, economical and capable of producing high-quality products.

Laying and assembly: The balance layer, HDF base material layer, decorative layer and wear-resistant layer (initially a transparent paper impregnated with melamine and alumina) are precisely laid together in sequence.

High-temperature and high-pressure fusion: The assembled laminated materials are fed into a huge continuous flat press. The press applies extremely high temperatures (approximately 200°C) and pressures (exceeding 300 psi). Under such conditions, the resin in each layer will melt, flow and cross-link, permanently curing all layers into a hard, dense and indivisible composite board.

Cooling and curing: The continuous plates coming out of the press will undergo a slow cooling process to ensure that the resin is fully cured, stabilize the internal structure of the plates, and eliminate internal stress.

Precision cutting and lock forming: The stabilized continuous large plates are precisely cut at high speed into floor panels of the required size. Subsequently, a CNC milling machine equipped with super-hard alloy tools was used to precisely mill out the lock rings on the four sides of the plate. The male tenon and female groove of the lock must fit seamlessly. This is the technical core for achieving glue-free installation, tight gaps and convenient installation.

Quality inspection and packaging: Each piece of flooring undergoes strict inspection both automatically and manually to eliminate defective products. Qualified products are packed into boxes of a certain area and prepared for leaving the factory.

B. High-pressure Lamination (HPL) - A high-performance manufacturing process

The HPL process is used to manufacture top-grade commercial and high-end household flooring, and its durability far exceeds that of DPL products.

Independent manufacturing of wear-resistant surface layer: Firstly, the decorative layer is superimposed with several layers of kraft paper impregnated with phenolic resin, and then subjected to extremely high pressure (over 1000 psi) and high-temperature treatment far exceeding DPL in a dedicated press. This forms an extremely tough, thick and independent wear-resistant surface layer.

Bonding to the substrate: This prefabricated, robust surface layer is then firmly bonded to the HDF substrate under high pressure with a high-strength adhesive.

The core difference: DPL is a one-time lamination of all layers, while HPL first creates an extremely wear-resistant surface layer and then combines it with the substrate. Therefore, the wear-resistant layer of HPL flooring is thicker, extremely wear-resistant and impact-resistant, and usually can meet commercial standards of AC5 or even higher.