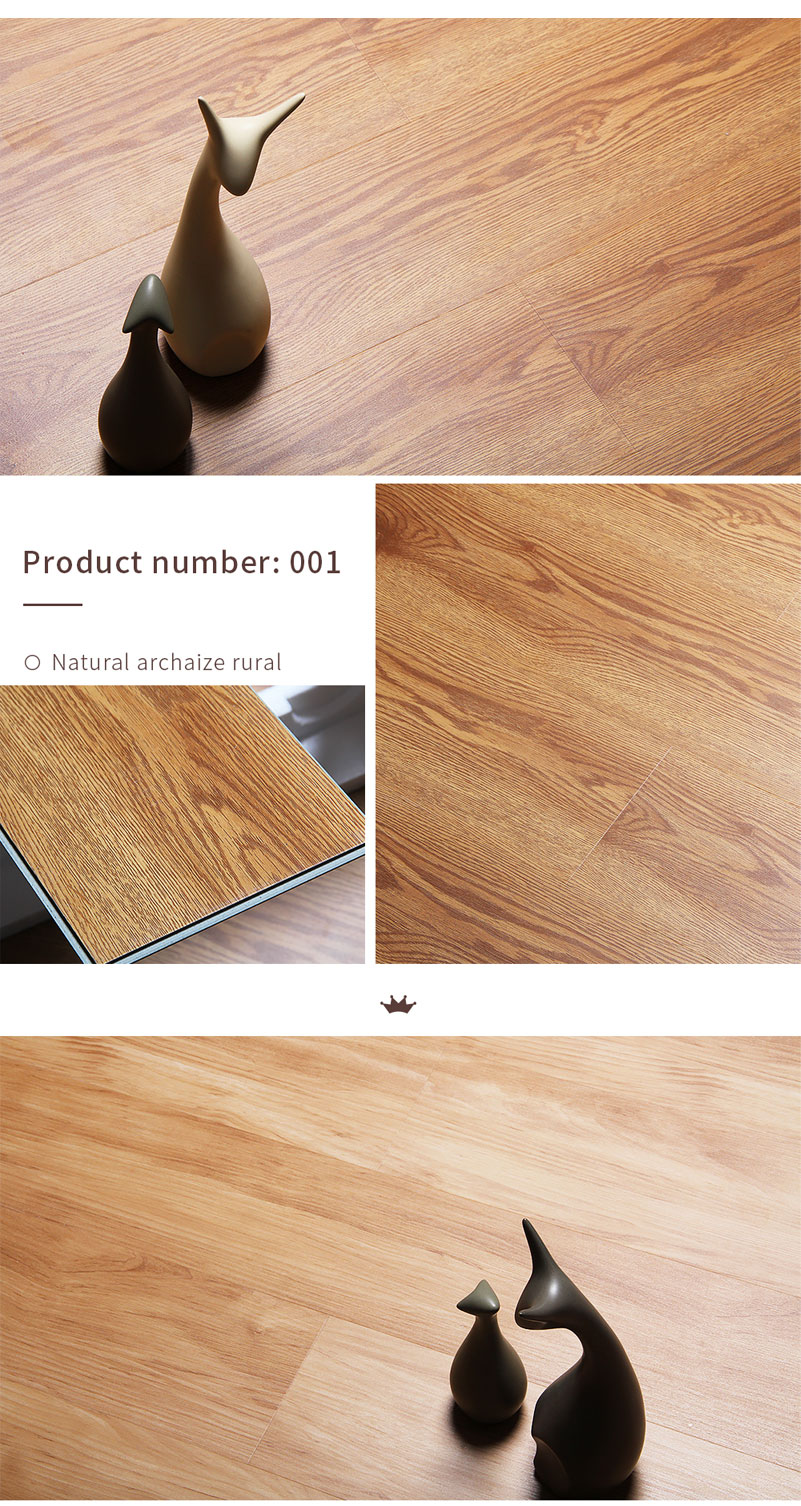

Rustic Laminate Flooring

Technical Advantages of SPC Flooring

SPC flooring exemplifies exceptional craftsmanship through its multi-layered refined design features. The surface textures, meticulously engineered via advanced embossing technologies to replicate authentic wood grain or stone textures, introduce natural elegance into interior spaces with high-fidelity material mimicry. Its sophisticated click-lock interlocking system ensures precise plank alignment, achieving a seamless and uniform installation finish that minimizes thermal expansion gaps. The application of advanced anti-slip coatings enhances safety performance by maintaining coefficient of friction values above industry standards (≥0.6), even under wet conditions. Laser-cut edge precision and standardized dimensional tolerances (±0.1mm) enable rapid installation while ensuring minimal joint spacing, contributing to a visually polished and architecturally consistent floor surface. Proprietary color stabilization processes guarantee inter-plank color uniformity within ΔE ≤1.5, eliminating noticeable chromatic variations and enhancing visual harmony. Additionally, its integrated sound-dampening layer reduces impact noise by ≥15 dB, meeting acoustic performance criteria for residential and commercial environments. These synergistic design elements collectively position SPC flooring as a premium flooring solution with superior technical performance and aesthetic consistency.

Product Technical Details

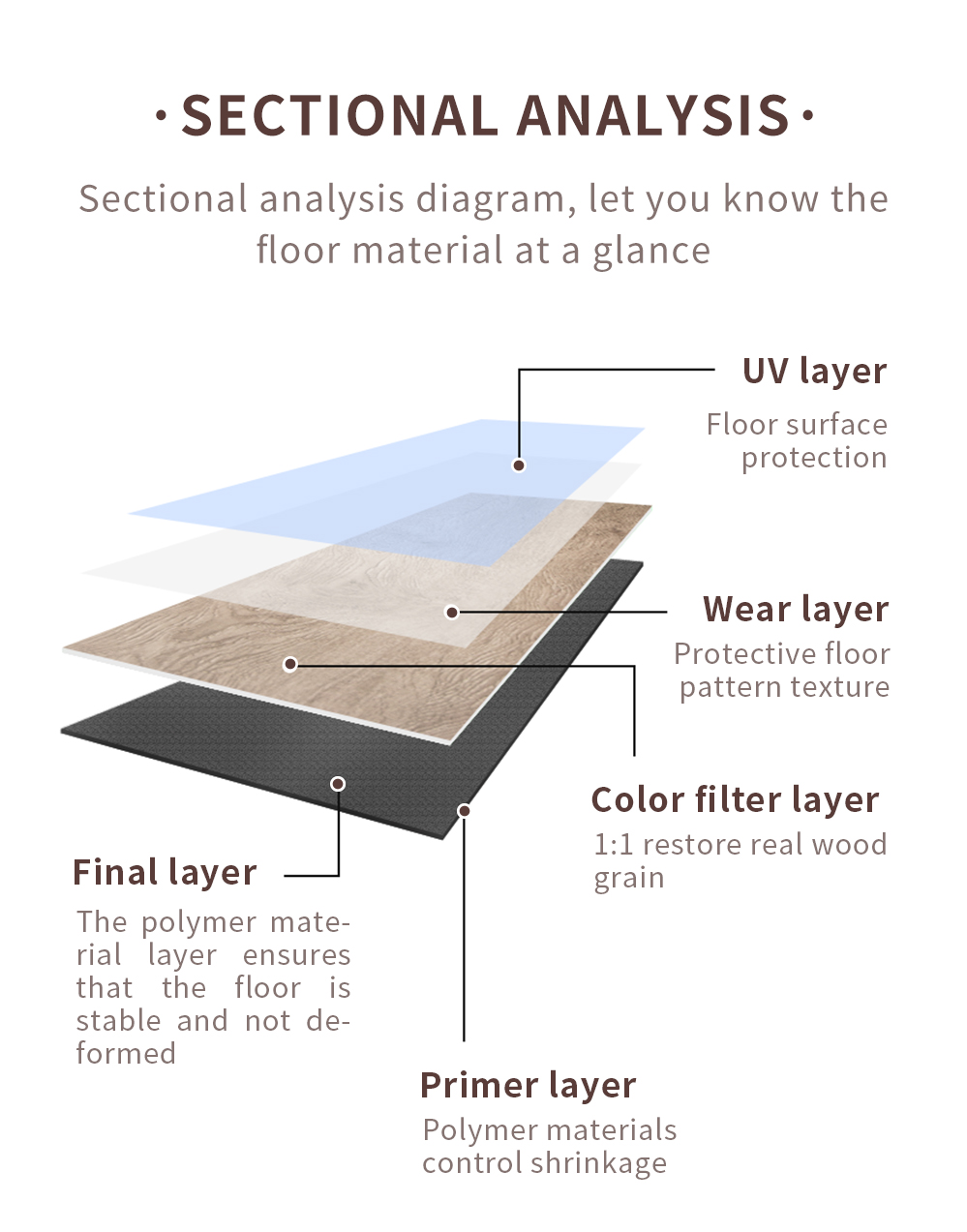

Layered Architecture

Top Surface System: A co-integrated UV-cured wear layer (≥3H hardness, ASTM D3363) bonded to a high-resolution decorative film. Embossing achieves ≥95% visual fidelity to wood/stone textures. Total thickness ≤1.5mm, featuring ≤0.08g/1000 cycles Taber abrasion resistance.

Structural Core Layer: High-density calcium silicate composite matrix (compressive strength ≥35MPa) blended with natural stone aggregates (≤180μm). REACH SVHC compliant, ECO-certified, formaldehyde-free, with VOC emissions ≤10μg/m³.

Acoustic Insulation Layer (Optional):

Material: Hot-melt polymer (900-950kg/m³) or natural cork (porosity ≥70%).

Thickness: 1.0mm (standard) or 2.0mm (enhanced cushioning).

Performance: 7-11dB impact noise reduction (ISO 140-8).

Brand | Delin | ||||||||||

Product | SPC Flooring | ||||||||||

Thickness | 3.5 - 7.5mm | ||||||||||

Wearing layer | 0.2mm/0.3mm/0.5mm | ||||||||||

Packing specification | 12pcs/Carton 2.6644㎡ | ||||||||||

Commodity inspection | E0 environmentaprotection andfireproofing | ||||||||||

Surface technics | Imitation solid wood | ||||||||||

Main material | PvC viny! | ||||||||||

Durable years | 20 years | ||||||||||

Applicable place | Home、Apartment、Office、Villa | ||||||||||

The factory can be customized according to the sample, the factory has tens of thousands of colors. | |||||||||||

Final layer | The polymer mate-rial layer ensures that the floor isstable and not de-formed | |||||||||||

Wear layer | Protective floorpattern texture | |||||||||||

Primer layer | Polymer materials control shrinkage | |||||||||||

Color filter layer | 1:1 restore real wood grain | |||||||||||

Specifications with card slot | 1220*182*4mm | ||||||||||

Thickness | 4mm | ||||||||||

Wear layer | 0.3mm | ||||||||||

Quantity | 12pcs/carton | ||||||||||

Area | 2.6644m² | ||||||||||

《Certificate of compliance》 | |||||||||||

《CCTV-7 honorary exhibition brand》 | |||||||||||

《China forest certification enterprise》 | |||||||||||

《Quality management system certification》 | |||||||||||

《China environmentallabeling productcertification certificate》 | |||||||||||

《Innovation Award for the l0th anniversary ofChina's forest products industry》 | |||||||||||

《10th anniversary contribution award of China'sforest products industry》 | |||||||||||

《Assured fidelity products and brand protectionproducts in the national consumer market》 | |||||||||||

Corporate Overview

Delin Wood Industry (Shandong) Co., Ltd. (est. 2010) is a vertically integrated manufacturer specializing in R&D, production, and global distribution of laminate flooring, engineered wood flooring, and SPC vinyl flooring. The company operates advanced automated production lines within a 30,000㎡ facility, supported by >100 technical professionals. Its operational model integrates advanced manufacturing with sustainable protocols, demonstrating commitment to innovation and environmental stewardship.

Certifications & Capabilities

ISO 14001:2015: Environmental management system featuring closed-loop recycling and low-carbon production.

ISO 9001:2015: Total Quality Management (TQM) system ensuring end-to-end quality control.

SGS Certified: Third-party verification for chemical safety (formaldehyde ≤0.05mg/m³, EN 717-1) and structural integrity, ensuring global compliance.

Manufacturing Capabilities

Scale: 500,000㎡ monthly capacity via intelligent production scheduling.

Customization: >100 standard color schemes + bespoke OEM/ODM services (texture embossing, surface treatments).

Market Leadership

With 15+ years of expertise, Delin is a globally renowned premium flooring solutions provider.

Technical Competence & Export Expertise

Our company deploys automated production lines integrated with precision German engineering, ensuring high-efficiency manufacturing processes and premium product quality. Backed by an ISO 9001:2015/ISO 14001:2015 certified quality management system, we enforce rigorous quality control protocols at every production phase. With over two decades of global export experience, we maintain a monthly shipping volume of 20+ 40-foot containers to over 20 countries, ensuring full compliance with CE, SGS, and regional safety standards (e.g., ASTM in North America, EN in EU).

Key FAQ Compilation

Corporate Profile

Founded in 2010 in Shandong, China, our manufacturing facility operates within a 30,000㎡ state-of-the-art production campus with a workforce of 51-100 skilled professionals. Current global market penetration includes:

30% market share in the Middle East

30% market presence in North America

10% regional dominance in East Asia

Quality Assurance System

Our quality management framework includes:

Pre-production Validation: Mandatory approval of engineering prototypes (PP samples) before mass production

End-to-End Inspection: 100% final quality control check for dimensional accuracy (tolerance ±0.1mm), surface finish, and mechanical properties (e.g., impact resistance ≥1.5J, ISO 179)

Certification Compliance: All products meet SGS-certified safety standards (e.g., formaldehyde emission ≤0.05mg/m³, EN 717-1) and hold CE marking for EU market access

Product Lineup

Our diversified portfolio comprises:

Laminate Flooring (AC3-AC5 wear ratings)

SPC Vinyl Flooring (ISO 10582 compliant, slip resistance ≥0.4μ)

Engineered Wood Flooring (multi-ply construction, FSC-certified options)

Solid Wood Flooring (naturally aged timber, moisture content 8-12%)

Bamboo Flooring (carbonized/untreated variants, hardness ≥1,100 Janka)

Competitive Differentiators

Industry Tenure: 22+ years of vertical integration from raw material sourcing to finished product

Customization Capability:

100+ standard color palettes (RAL/NCS systems)

Bespoke design services including embossing patterns and edge profiling

Manufacturing Scale: 500,000㎡ monthly production capacity with flexible batch sizing (MOQ 500㎡ for custom orders)

Global Service Infrastructure

Payment Flexibility: Acceptance of 12 major currencies (USD, EUR, CNY, GBP, JPY, etc.) via L/C, T/T, and digital payment platforms

Multilingual Support: 24/7 customer service in 12 languages (English, Spanish, Arabic, French, Russian, etc.) with dedicated regional account managers