Engineered Pine Flooring: The Sustainable and Stable Choice for Modern Global Projects

Engineered Pine Flooring: The Sustainable and Stable Choice for Modern Global Projects

In the evolving landscape of global construction and interior design, the demand for flooring solutions that harmonize aesthetic appeal, structural performance, and environmental responsibility continues to rise. Among the versatile options available to contractors, developers, and distributors, engineered pine flooring has emerged as a premier choice. This innovative product masterfully combines the timeless warmth and character of pine with advanced manufacturing technology, delivering a product designed for the rigors of international trade and diverse climatic conditions.

For B2B buyers sourcing materials for large-scale residential, commercial, or hospitality projects, understanding the value proposition of engineered wood flooring, specifically in pine, is crucial. This article delves into the technical advantages, market dynamics, and key considerations that make this product category a smart and sustainable investment.

Market Position and Growing Demand for Engineered Wood

The global market for engineered wood flooring demonstrates consistent growth, driven by several key factors. Increasing urbanization, a boom in renovation and retrofit projects, and a pronounced shift toward sustainable building materials form the core of this demand. Engineered pine flooring sits at a strategic intersection within this trend.

Pine, as a species, is renowned for its fast growth and renewability, making it an inherently sustainable resource. When utilized in an engineered core, it maximizes yield and reduces waste compared to traditional solid wood planks. Buyers are increasingly specifying materials with robust environmental credentials, and engineered pine flooring directly answers this call. Its suitability for use with underfloor heating systems, a standard in many modern builds, further broadens its application scope across various international markets.

Technical Superiority: Deconstructing the Engineered Pine Floor

The Multi-Layer Structure: Engineered for Stability

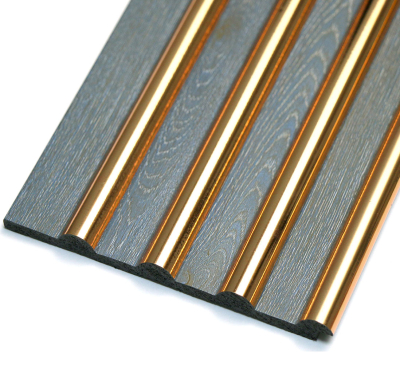

The fundamental advantage of engineered pine flooring lies in its cross-layered construction. A typical board consists of:

Top Wear Layer (Lamella): This is a solid layer of premium pine, determining the floor's final appearance and wear characteristics. Its thickness, which can vary, dictates the number of potential refinishes over the product's lifetime.

Core Layers: Beneath the wear layer are multiple piles of cross-bonded softwood or HDF (High-Density Fiberboard). Each layer's grain runs perpendicular to the adjacent one. This revolutionary structure counteracts the natural tendency of wood to expand and contract with humidity and temperature fluctuations.

Balancing Backing Layer: The bottom layer ensures overall panel stability and prevents cupping or warping.

This construction grants engineered pine flooring for commercial use exceptional dimensional stability, allowing it to be installed in environments where solid wood would be risky, such as over concrete subfloors or in areas with variable humidity.

Advanced Finishes and Treatments

Modern production lines apply sophisticated finishes that enhance durability and ease of maintenance. These include:

UV-Cured Polyurethane or Oil Finishes: These provide a hard, protective surface resistant to scratches, stains, and wear, making durable pine wood flooring suitable for high-traffic areas.

Brushed and Oiled Surfaces: This treatment highlights the natural grain texture of the pine, offering a rustic, tactile feel that is highly sought after in contemporary design.

Pre-finished Quality: Factory-applied finishes ensure uniform coating thickness, faster installation times, and immediate usability upon installation, a critical factor for project timelines.

Application and Installation Versatility

Engineered pine flooring is designed for versatile installation methods, which is a significant benefit for professional installers. The most common methods include:

Floating Installation: Planks are clicked or glued together over an underlay, without being nailed to the subfloor. This is a fast, efficient method ideal for large areas.

Glue-Down Installation: The flooring is fully adhered to the subfloor, recommended for concrete slabs or commercial applications requiring supreme stability.

Nail-Down Installation: Suitable for wood subfloors, this traditional method provides a secure fit.

Its stability makes it an excellent candidate for installing engineered pine over underfloor heating, a key selling point in European and other temperate markets.

Frequently Asked Questions (FAQ) for B2B Buyers

Q1: How does engineered pine flooring compare to solid pine flooring in terms of performance?

A1: Engineered pine offers superior dimensional stability due to its cross-ply construction, making it less susceptible to gapping, cupping, and warping caused by humidity and temperature changes. This makes it more reliable for export, installation over various subfloors, and use in geographies with distinct seasons.

Q2: Is engineered pine flooring suitable for commercial projects like retail spaces or offices?

A2: Absolutely. When specified with a thick wear layer and a robust commercial-grade finish, engineered wood flooring for high-traffic areas made from pine is a durable and aesthetically pleasing option. Its stability and ease of maintenance are significant advantages in commercial settings.

Q3: Can engineered pine floors be sanded and refinished?

A3: Yes, this is a major advantage over laminate flooring. The number of times it can be refinished depends on the thickness of the top solid pine wear layer. Quality products with a thick wear layer (e.g., 4mm or more) can be refinished several times, significantly extending the floor's lifespan.

Q4: What are the primary sustainability benefits of sourcing engineered pine flooring?

A4: The engineered structure optimizes the use of fast-growing pine timber, reducing waste. Many reputable manufacturers source from sustainably managed forests (FSC® or PEFC™ certified) and use low-VOC adhesives and finishes. This results in a lower environmental footprint compared to many flooring alternatives.

Partner with a Supplier for Quality and Consistency

Selecting the right supplier is paramount for B2B success. Look for manufacturers who provide comprehensive technical data sheets, compliance certificates (such as CE marking, CARB Phase 2, or EPDs), and consistent quality control. A reliable partner will offer a range of grades, finishes, and specifications of prefinished engineered pine to meet diverse project requirements, from rustic to modern aesthetics.

Take the Next Step in Your Sourcing Strategy

As the global market continues to prioritize sustainable, stable, and aesthetically versatile building materials, engineered pine flooring stands out as a forward-thinking solution. We encourage B2B buyers, project managers, and distributors to evaluate this product's technical merits and market potential.

Contact our expert team today to request detailed specifications, compliance documentation, and discuss how our engineered pine flooring can meet the precise needs of your upcoming projects. Let us provide you with the information necessary to make an informed, profitable sourcing decision.