Elevate Interiors with Gloss Laminate Flooring

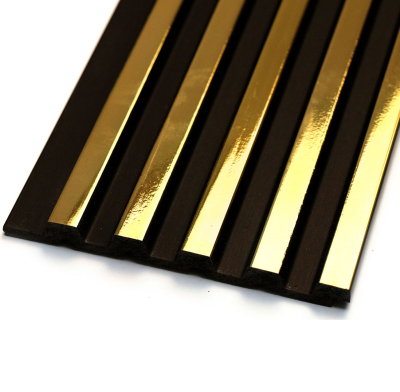

Gloss Laminate Flooring: A Premium Choice for Modern Commercial & Residential Spaces

The global flooring industry is witnessing a significant shift towards materials that combine aesthetic appeal with practical performance. Among these, high-gloss laminate flooring has emerged as a standout category, experiencing sustained growth driven by its ability to deliver a luxurious, contemporary look at a competitive price point. For B2B buyers sourcing flooring solutions for projects ranging from upscale residential complexes to modern commercial venues like boutiques, showrooms, and corporate offices, understanding the nuances of this product is key to capitalizing on market demand. This article delves into the benefits of gloss laminate flooring, current market trends, technological advancements, and its position within the broader interior design landscape.

Market Landscape and Growth Drivers for Laminate Flooring

The laminate flooring market continues to expand robustly, with a projected compound annual growth rate (CAGR) of approximately 5-7% over the next five years, according to recent industry analyses. This growth is fueled by several factors: a resurgence in global construction and renovation activities, rising consumer disposable income, and a heightened focus on quick-installation, cost-effective solutions that do not compromise on style.

Within this upward trajectory, the glossy finish laminate segment commands a premium niche. Its appeal lies in its ability to mimic the reflective, sleek surface of polished marble or high-gloss lacquered wood, while offering the inherent advantages of laminate – namely, exceptional durability, ease of maintenance, and resistance to fading and stains. The demand for easy to clean laminate flooring has been particularly pronounced in commercial settings and busy households, where both hygiene and visual impact are paramount.

Dominant Trends: What Buyers Are Looking For

Today’s B2B buyers and their end-consumers are informed and value-driven. Several key trends are shaping the gloss laminate flooring market:

Sustainability and Eco-Consciousness: There is a growing preference for products manufactured with sustainability in mind. Buyers increasingly seek laminate flooring produced using recycled materials, formaldehyde-free adhesives (often certified by standards like CARB Phase 2 or E0), and processes that minimize environmental impact. Certifications from bodies like the Forest Stewardship Council (FSC) or GREENGUARD are powerful selling points.

Hyper-Realistic Designs and Large Formats: Advancements in direct-pressure laminate (DPL) and high-definition (HD) print technologies have revolutionized design fidelity. Modern gloss laminate floors now feature incredibly realistic wood grain textures, stone veining, and even abstract patterns. Coupled with longer and wider plank formats (e.g., 7-inch wide, 60-inch long), these designs create seamless, spacious-looking interiors with fewer visible joints.

The Rise of Textured Finishes: While the surface remains highly reflective, there is a move towards combining high-gloss finishes with subtle, authentic textures like brushed, hand-scraped, or embossed wood grains. This “textured-gloss” effect reduces the visibility of footprints and minor scratches, enhancing both practicality and tactile appeal.

Performance-Oriented Features: The market is moving beyond basic AC ratings (Abrasion Class). Buyers look for enhanced features such as waterproof or water-resistant cores (using technologies like stone-plastic composite (SPC) or wood-plastic composite (WPC) integrated with laminate layers), attached underlayment for sound absorption, and improved scratch and impact resistance coatings.

Technology Behind the Shine: Manufacturing Insights

Creating the signature high-shine laminate surface is a precise engineering feat. The process typically involves the following key stages in manufacturing:

Base Layer (Core): A high-density fiberboard (HDF) core provides structural stability, density, and moisture resistance. Some premium lines use polymer-enhanced cores for superior waterproof performance.

Decorative Layer: A high-resolution photographic paper is printed with the desired design (oak, marble, etc.). This layer is what gives gloss laminate flooring its visual character.

Overlay and Wear Layer: This is the most critical component for gloss finishes. A clear melamine or aluminum oxide wear layer is applied. To achieve the gloss effect, this layer is cured and pressed using highly polished plates. The smoothness and clarity of this top coat determine the depth and quality of the gloss, ranging from a soft satin sheen to a mirror-like high-gloss effect.

Finishing: The planks are then precision-cut with click-lock systems (like Unilin or Välinge) for easy, glue-free installation. The back is often treated with a stabilizing balance layer.

This multi-layer construction ensures that the glossy surface is not just a superficial coating but a deeply integrated, durable component designed to withstand years of foot traffic.

Frequently Asked Questions (FAQ) for B2B Buyers

Q1: Is gloss laminate flooring suitable for high-traffic commercial areas?

Absolutely. Modern commercial grade gloss laminate is engineered with high AC ratings (AC4, AC5, or higher). The tough aluminum oxide wear layer provides excellent resistance to scratches, scuffs, and wear, making it ideal for retail stores, office lobbies, and other commercial applications where both aesthetics and durability are crucial.

Q2: How does it compare to real polished wood or stone in terms of maintenance?

Gloss laminate flooring offers significantly easier maintenance. It requires only regular sweeping and occasional damp mopping with a manufacturer-recommended cleaner. Unlike real wood or stone, it does not need periodic waxing, polishing, or sealing to maintain its shine. Its non-porous surface is also more resistant to stains.

Q3: Does a glossy floor show scratches and footprints more easily?

While a pristine glossy surface can be more reflective of light and thus may show dust and footprints slightly more than a matte finish, modern textured gloss laminate options mitigate this effectively. Furthermore, the advanced wear layers are specifically designed to be scratch-resistant. For most settings, regular cleaning is sufficient to maintain its impeccable appearance.

Q4: What are the key specifications I should request when sourcing?

Essential specifications include: AC Abrasion Class Rating (for traffic durability), Thickness (e.g., 8mm, 10mm, 12mm), Water Resistance (look for waterproof core technology for wet areas), Formaldehyde Emission Class (E0 or CARB2 compliant), Plank Dimensions, and the type of Click-Lock System. Always ask for certified test reports from suppliers.

Conclusion: A Strategic Choice for Discerning Buyers

Gloss laminate flooring represents a sophisticated fusion of design ambition and practical engineering. It answers the market’s call for luxurious, light-enhancing interiors without the high cost and demanding upkeep of natural materials. For B2B buyers, sourcing this product means offering clients a compelling value proposition: transformative aesthetics, proven resilience, and straightforward installation.

As the industry continues to innovate with more realistic designs, enhanced waterproof properties, and sustainable production methods, the position of high-gloss laminate as a versatile and desirable flooring solution will only strengthen.

Ready to elevate your project portfolio with premium, high-performance gloss laminate flooring? Contact us today to discuss your specific requirements, request detailed technical data sheets, and explore our comprehensive, trend-forward collection designed for the global market. Let us partner with you to deliver floors that impress and endure.