Can cracking occur in SPC flooring?

Will SPC flooring crack?

The short answer is: Yes, SPC (stone plastic composite) flooring can crack, but it is not common under appropriate conditions, and compared with many other types of flooring, it has a high crack resistance. The perception that SPC is an indestructible material is a misunderstanding. Although it is one of the most stable and rigid elastic floor options on the market in terms of size, it cannot avoid failure when the basic principles of installation, base preparation and environmental physics are ignored.

This analysis will delve deeply into the multiple reasons behind SPC cracking, going beyond simple answers and exploring materials science, installation key factors, and environmental factors from a global professional perspective.

1. Understanding the anatomy of SPC: Why Is It such a resilient Start

To understand why it cracked, we must first know its engineering strength. A typical SPC sheet is a multi-layer laminated product:

Wear-resistant layer: A transparent and durable coating (typically polyurethane-based and alumina) that can resist scratches, stains and wear.

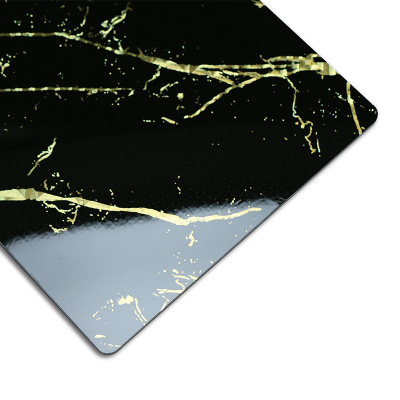

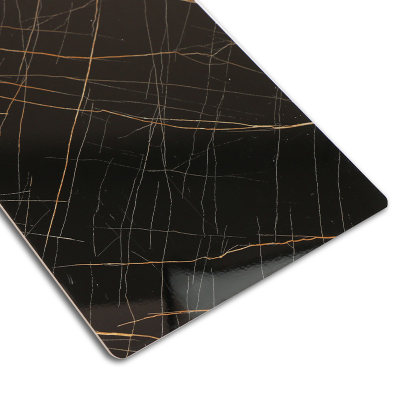

Print layer: A high-resolution photographic film with wood, stone or abstract patterns on it.

SPC core: This is the core of the product. It is a dense and hard composite material, mainly composed of:

Limestone powder (calcium carbonate) : Main filler, providing quality and density.

Polyvinyl chloride (PVC) : Adhesive, endowing the core material with flexibility and cohesion.

Stabilizer: Enhances thermal stability and UV stability.

What is the core difference between SPC and its cousin, WPC (wood-plastic composite)? SPC cores have a higher limestone-to-plastic ratio, making them exceptionally hard, dense and dimensionally stable. It does not expand or contract with changes in temperature and humidity to the same extent as wood or even wood-plastic composites.

Substrate adhesion: Many SPC products come with pre-attached foam substrates. This layer offers sound insulation, minor floor defect forgiveness, and comfort underfoot.

Inherent strength: High-density SPC cores have strong resistance to indentation and crushing. Its rigidity is its main defense against many common floor problems. However, when confronted with specific stressors, this rigidity becomes its fatal weakness.

2. The main culprit: Why does SPC flooring crack

Cracking of SPC flooring is almost never a spontaneous material defect. It is a symptom of a potential problem and usually falls into one of the following categories.

A. Defects in the base plate: The primary cause of failure

So far, this is the most common cause of cracking in global SPC installations. The principle is simple: SPC is rigid, not flexible. It won't bend to fit the uneven base plate. On the contrary, it will build Bridges in inclined and raised areas and create gaps under the planks.

Point load and stress concentration: When weight (for example, a person walking, refrigerator legs, high heels) is directly applied to these gaps, the wooden board has no potential support. The force is concentrated in a very small area. Because SPC cores are brittle under such concentrated bending stress, they can exceed their tensile strength and develop cracks, usually with sharp, clean fractures.

Professional Standards : The global industry standards formulated by manufacturers and institutions such as the NWFA (National Wood Flooring Association) and FCICA (Floor Contractors Association) are extremely strict. Most SPC manufacturers require the base plate to be flat to a radius of 3/16 "exceeding 10 feet (or 3mm exceeding 1 meter). If this tolerance cannot be met, most guarantees will be invalid and the risk of cracking and joint failure will be greatly increased.

B. The installation and expansion gap are incorrect

Although SPC has superior dimensional stability, it is still affected by thermal expansion. The core and the attached substrate can expand and contract with significant fluctuations in temperature.

Lack of expansion gaps:If the floor is installed too tightly against all vertical obstacles (walls, cabinets, door frames, pipes), there will be nowhere to go when it expands. As there is no room for relaxation, the wooden boards press against each other and the fixed objects form a huge compressive force. This force has only one way to be released: by making the wooden board "tent" (lifting at the seams), or in severe cases, breaking under pressure, usually on the locking mechanism or the body of the wooden board.

Improper tapping and force: Click-lock systems (Unilin or Valinge) are designed for specific combinations. During the installation process, applying excessive force with tapping blocks and hammers can cause the precise locking mechanism to be stressed or even break. Micro-cracks during installation can expand into complete cracks under subsequent loads or expansion pressures.

C. Impact damage and overload

Although highly resistant to indentation, the rigidity of the SPC core makes it vulnerable to catastrophic damage from sharp and high-impact forces. When heavy and sharp objects, such as cast iron frying pans or tools, fall from a height, they will generate an impact force exceeding the material's impact strength, causing star-shaped or linear cracks. This is a physical issue, not a product defect.

D. Product quality and manufacturing defects

Although not very common, it is a factor in the global market, with a wide range of quality levels.

Low-quality core formula: Inferior SPC products may use an unbalanced ratio of limestone to PVC. Excessive limestone without sufficient PVC adhesive can make the core chalky, brittle and even prone to cracking under normal load. A core with excessive PVC may become softer and lose the key rigidity advantage of SPC.

Fault Locking system : A poorly ground locking profile may not correctly distribute the load on the wood board, causing weaknesses. If "clicking" feels unsafe during dry fitting, it is a danger signal.

Micro-cracks caused by transportation and handling: The wooden boards may be damaged during transportation or even before reaching the workplace. These cracks can be hairline and invisible until the planks are installed and stepped on.

3. Distinguish cracks from other problems

It is crucial to distinguish genuine cracks from other common problems

Cracks and Fragmentation: Cracks are fractures that propagate through materials. Peeling is a small piece of the worn layer or core that falls off, usually at the edge of the board, typically due to an improper installation Angle or impact.

Crack vs Peak/Tent: This occurs when the joints between the planks are pushed upwards, forming a ridge. This is almost always caused by the lack of expansion space rather than material faults of the board itself, although it can lead to cracking over time.

Cracking and delamination: Delamination refers to the separation of layers (the worn layer from the printed layer, or the core layer from the adhered substrate), usually due to moisture or the failure of the manufacturing adhesive.

4. Global professional perspective: Regional considerations

Best practices are universal, but there are also regional challenges:

Europe (EU) : The European market, especially Germany and the Scandinavian Peninsula, has a long history of high-quality hard-core flooring.

5. Prevention: Professional installation signs

Preventing SPC cracking is a systematic process:

1. Meticulous underlying inspection and preparation: This is non-negotiable. Professionals use long rulers and laser levels to identify high and low points. Defects must be corrected by grinding out the high points and filling the low points with a self-leveling substrate.

2. Strict moisture test : Even if SPC is 100% waterproof, the base plate must still undergo testing. Excessive moisture can cause mold, mildew and the failure of the substrate adhesive, thereby affecting the support.

3. Adaptability : Although SPC requires less adaptability than wood, the best practice is to allow the box to adapt to the room temperature for 24-48 hours before installation. This can prevent contraction or expansion after installation.

4. Strictly adhere to expansion clearance: It is essential to maintain a consistent 1/4 "to 3/8" clearance around all periphery and fixed objects. These gaps were later covered up with skirting boards or molds.

5. Correct installation techniques: Using the right tools, meshing the lock at the correct Angle, and avoiding excessive force are basic skills.

6. Select high-quality products : It is crucial to purchase from reputable manufacturers who offer complete technical data sheets and strong guarantees. Cheaper products often mean more vulnerable cores and a higher risk of failure.

Conclusion

So, does SPC flooring crack? The evidence confirms that it can, but it is a failure of the system, not an inherent flaw of the material. The exceptional rigidity and dimensional stability of the SPC core, its greatest assets, require a perfectly prepared and stable environment to perform as intended.

The occurrence of cracking is almost invariably a direct result of deviating from established professional protocols: an imperfect subfloor, a missing expansion gap, or improper installation force. From a global professional standpoint, the question is not *if* a brittle, rigid material *can* crack under extreme stress, but rather, how to engineer the installation system to ensure those stresses are never applied. When installed correctly over a properly prepared subfloor, SPC flooring is one of the most durable and crack-resistant floor coverings available, capable of providing decades of trouble-free service.