SPC Flooring For Kitchen

Effectively inhibits flame propagation, providing a critical layer of protection.

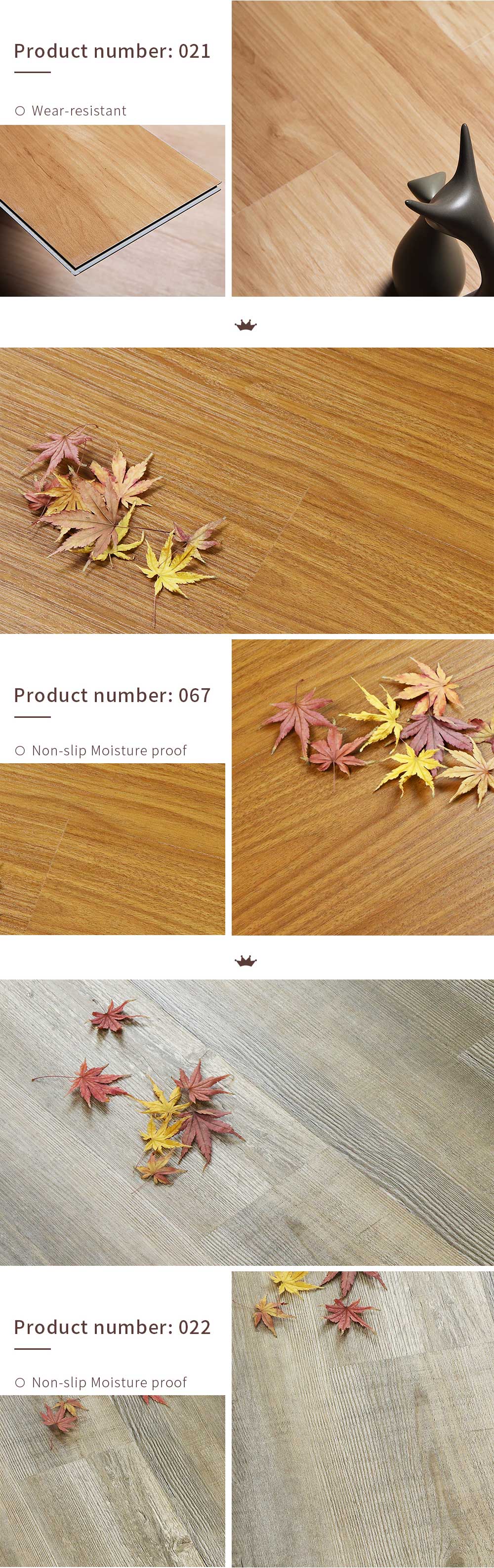

Crafted from high-density materials to resist scratches and wear, maintaining its pristine appearance even in high-traffic areas.

Specifically engineered for humid environments; it will not swell, warp, or deform from moisture exposure.

Manufactured without harmful chemicals, contributing to healthier indoor air quality.

Features a user-friendly locking mechanism that requires no glue or nails, making it perfect for DIY projects.

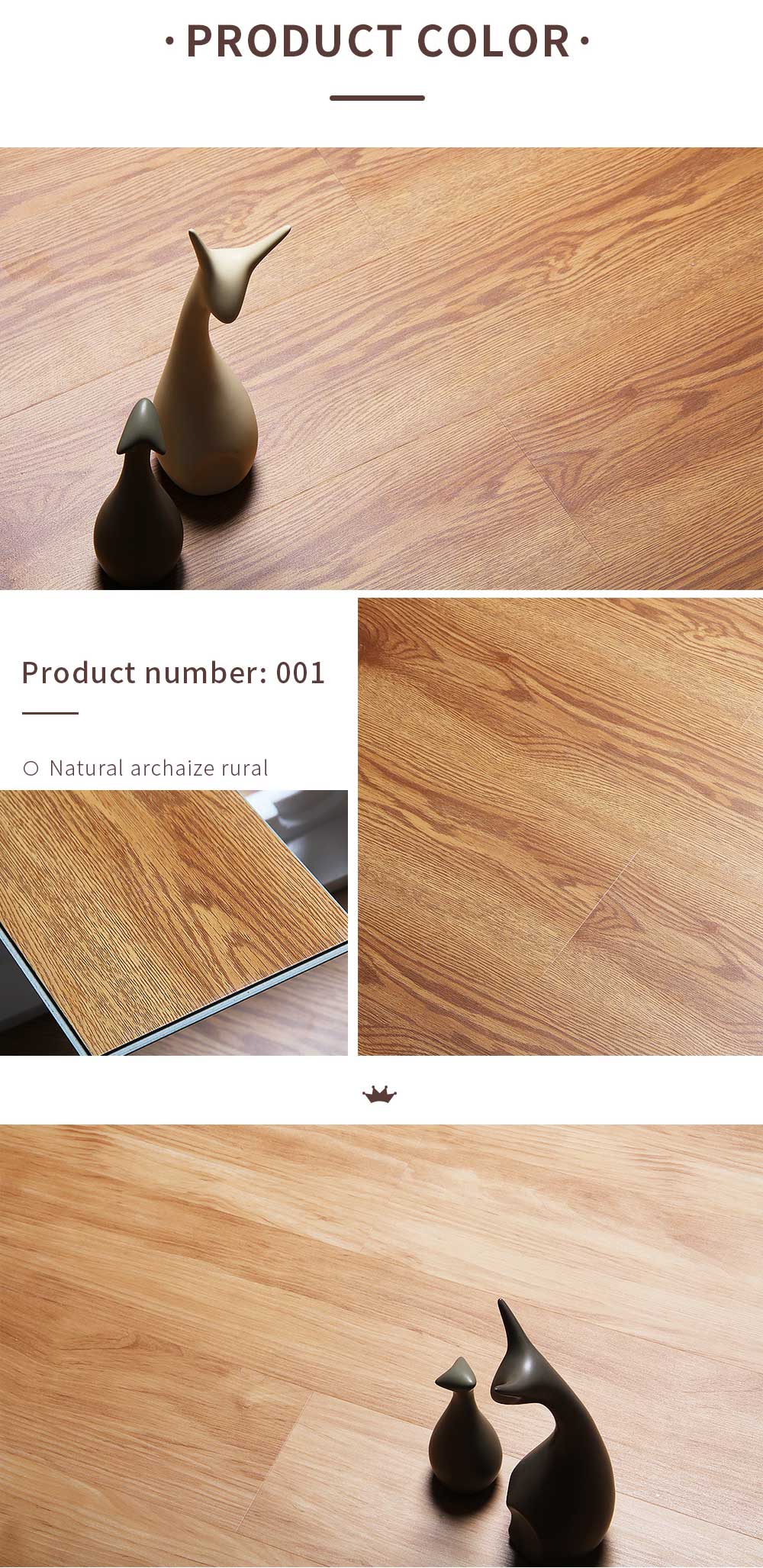

Offers a wide selection of colors and textures to seamlessly complement any design style.

Product Overview: Redefining Kitchen Flooring Standards

SPC Flooring for Kitchen is an innovative rigid core flooring product engineered specifically for high-moisture, high-traffic kitchen environments. Utilizing advanced Stone Plastic Composite (SPC) technology, this product integrates limestone powder, polyvinyl chloride, and stabilizers, formed under high temperature and pressure to create a flooring system of exceptional stability and durability. As the ideal choice for modern commercial and residential kitchens, SPC kitchen flooring perfectly balances functional performance with aesthetic appeal, offering global B2B buyers—including real estate developers, hospitality management groups, restaurant chains, and building material distributors—a truly worry-free flooring solution.

Superior Waterproof and Moisture-Resistant Properties

The 100% waterproof structure forms the foundation of SPC kitchen flooring. Its dense, rigid core completely resists water penetration, fundamentally eliminating issues common to traditional wood flooring, such as expansion, warping, and mold growth. This makes the product suitable not only for residential kitchens but also perfectly suited for the demanding requirements of commercial kitchen environments, which face extreme humidity and frequent cleaning. The waterproof nature of SPC flooring ensures long-term dimensional stability, maintaining its perfect condition even when consistently exposed to spills.

Easy Installation and Low Maintenance

Featuring an advanced click-lock system, SPC flooring allows for quick and seamless installation. Whether using a floating method or direct glue-down, installation is efficient, greatly reducing project timelines and labor costs. Daily maintenance is remarkably simple—routine sweeping and occasional damp mopping are sufficient to keep floors looking new. No waxing or special treatments are required, significantly lowering the total long-term maintenance cost for commercial kitchen flooring.

Exceptional Durability and Load-Bearing Capacity

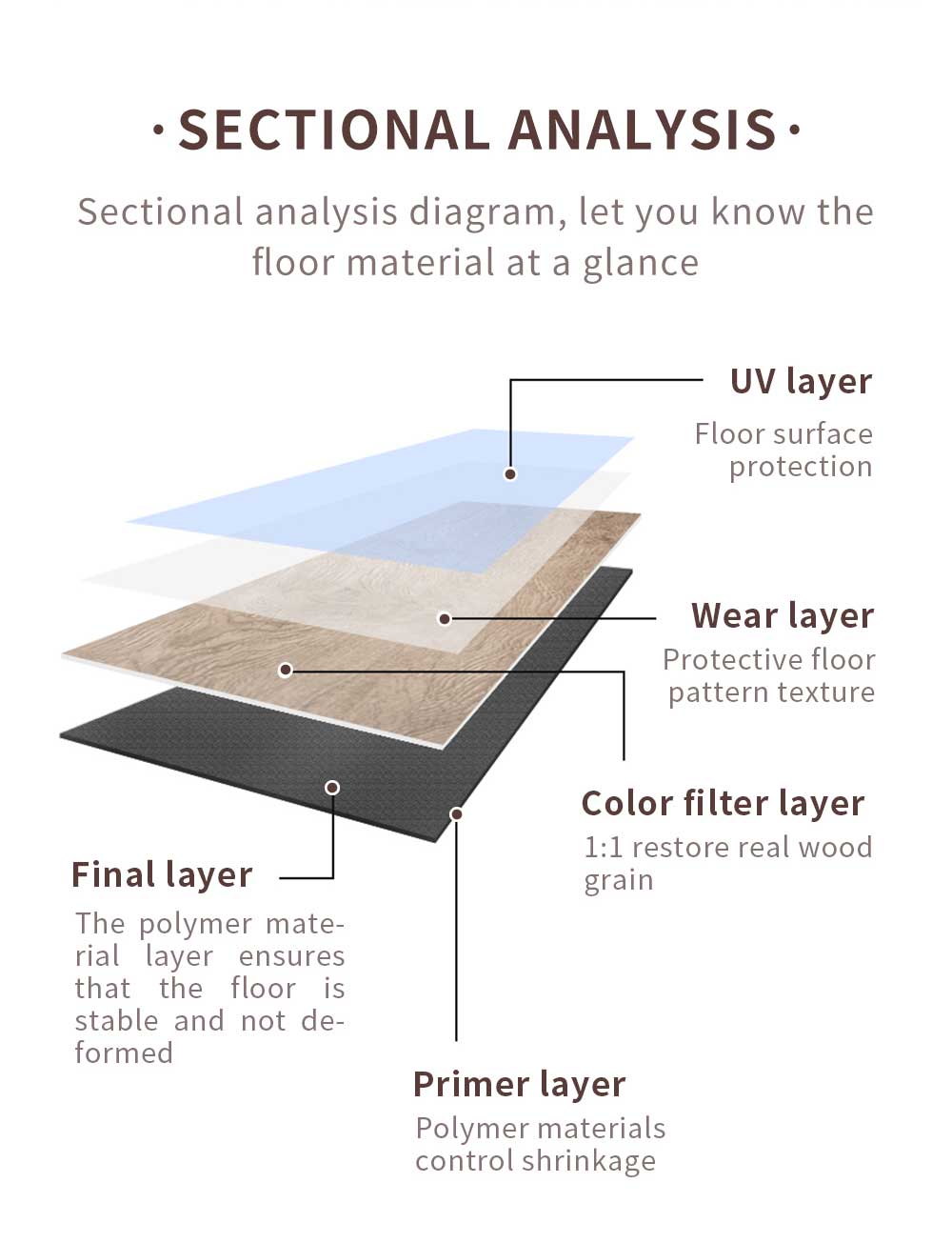

SPC flooring boasts high density and hardness, offering outstanding impact and scratch resistance. Its unique rigid core can withstand the pressure from heavy kitchen equipment, storage racks, and high foot traffic, significantly reducing the risk of indentations and wear. The wear layer, typically treated with a UV coating, provides excellent resistance to stains and household chemicals, easily repelling common kitchen contaminants like oils, sauces, and cleaning agents.

Evolving Aesthetics and Design Flexibility

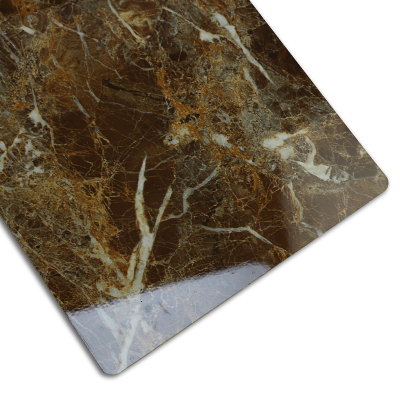

Today’s market demands more than just functionality. Buyers seek flooring that complements modern interior design. SPC flooring manufacturers have invested heavily in advanced printing and embossing technologies, producing planks and tiles that offer hyper-realistic replications of natural wood, stone, and concrete. The availability of varied formats, including wide planks, long lengths, and intricate tile patterns, allows for seamless integration into any kitchen design scheme, from rustic farmhouse to sleek minimalist.

Technical Specifications and Quality Assurance

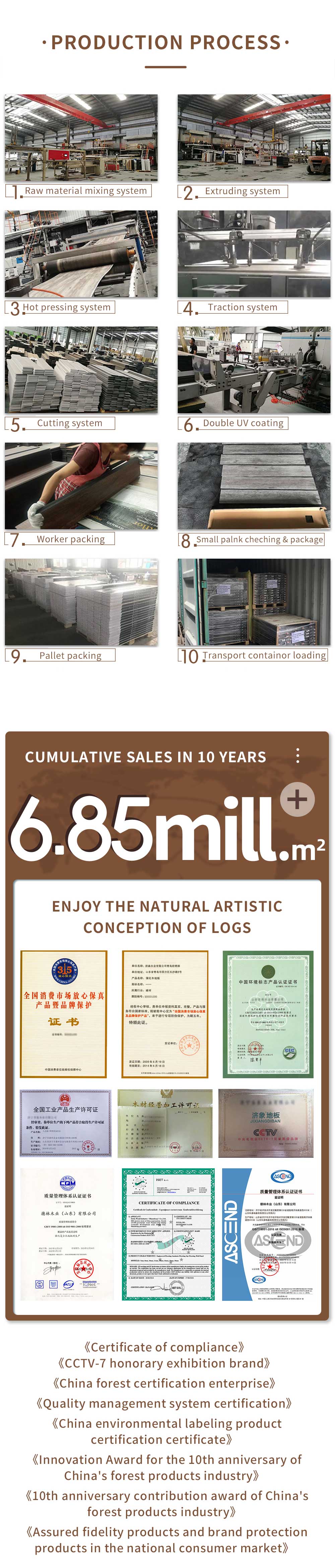

This product series offers various thickness options (typically from 3.5mm to 8mm) to meet different load-bearing and acoustic insulation needs. The decorative surface layer utilizes high-resolution printing technology to accurately replicate the appearance of natural wood, stone, or creative textures, complemented by a realistic embossed feel. All products comply with international authoritative certifications, including ISO standards, CE marking, FloorScore® indoor air quality certification, and REACH environmental standards, ensuring safety, durability, and environmental responsibility. The fire rating meets commercial building codes, providing solid compliance assurance for projects.

Frequently Asked Questions (FAQ)

Q1: What are the requirements for the subfloor when installing SPC flooring in a moist kitchen environment?

A: SPC kitchen flooring requires the subfloor to be level, dry, clean, and structurally sound. For concrete subfloors, moisture content must meet industry standards. The product can be installed over existing, level surfaces like ceramic tile or vinyl flooring, greatly simplifying renovation projects. A professional subfloor assessment prior to installation is recommended.

Q2: Can this product withstand extreme temperature fluctuations or occasional hot spills possible in a commercial kitchen?

A: Yes. SPC flooring has good thermal stability and can adapt to normal temperature variations in kitchen environments. Its wear layer also provides a degree of heat resistance, withstanding brief exposure to hot spills (e.g., dropped boiling water). However, using trivets or pot holders and avoiding placing extremely hot cookware directly on the floor for extended periods is recommended to preserve the optimal appearance.

Q3: Does the product comply with international environmental and food safety contact standards?

A: Absolutely. Our SPC Flooring for Kitchen is formulated with environmentally friendly materials. It is free from harmful substances such as phthalates and heavy metals. It meets strict international standards for indoor air quality and safety, making it a responsible choice for both residential and commercial food preparation areas.

Q4: Is SPC flooring suitable for use with underfloor heating systems in kitchens?

A: Yes, most of our SPC flooring for kitchen products are compatible with water-based underfloor heating systems, provided the manufacturer's specified maximum surface temperature (usually around 27°C / 80°F) is not exceeded. It is crucial to follow the specific installation guidelines for use with radiant heat. The product's stability helps minimize expansion and contraction due to temperature changes.