Does SPC flooring crack?

Will SPC Flooring Crack? – An In-Depth Analysis from a Professional International Perspective

Core Conclusion: Under correct installing SPC flooring procedures and normal usage conditions, high-quality SPC flooring itself is extremely unlikely to crack. The vast majority of reported "cracking" issues are not due to product defects, but rather result from substandard subfloor conditions, incorrect installation methods, or extreme accidental impacts. Understanding this distinction is crucial for scientifically evaluating the durability of SPC hybrid floors.

SPC (Stone Plastic Composite) flooring, a revolutionary rigid floor covering, has undergone extensive testing and application in global markets for many years, particularly in North America, Europe, and Australia. Its outstanding stability and durability form its core competitive advantage. To comprehensively address whether it will crack, an in-depth exploration from three dimensions is necessary: material science, installation standards, and usage and maintenance.

I. Material Science of SPC Flooring: The Inherent Advantage in Crack Resistance

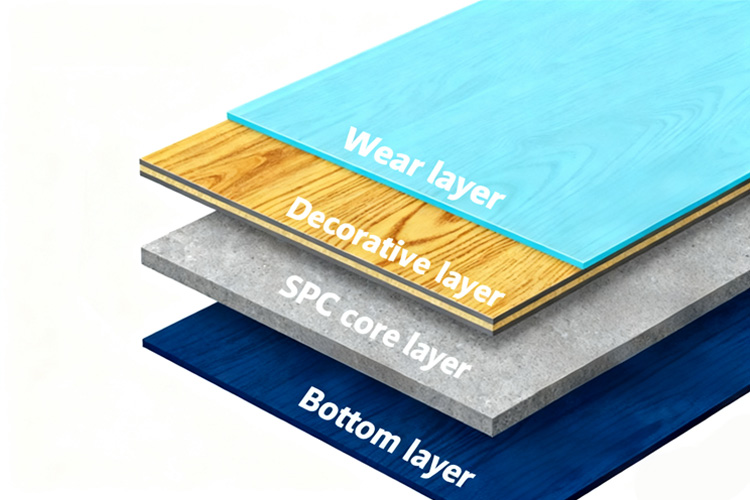

The structure of SPC flooring typically consists of four layers: the wear layer, the decorative layer, the SPC core layer, and the backing layer. The secret to its crack resistance lies precisely in its core layer.

1. Core Composition and Stability:The SPC core is primarily formed through high-temperature, high-pressure extrusion of limestone powder (calcium carbonate), polyvinyl chloride (PVC), and stabilizers. This composite material offers:

High Density and Rigidity: The stone powder gives SPC flooring a hardness and compressive strength similar to stone. Compared to laminate flooring (composed mainly of wood fibers) or solid wood flooring (sensitive to humidity), SPC is virtually unaffected by changes in environmental temperature and humidity. It does not expand by absorbing moisture from the air like wood, nor does it contract due to drying. This exceptional dimensional stability fundamentally eliminates common issues in traditional flooring, such as joint separation or board warping caused by "expansion and contraction."

Inertness and Weather Resistance: Both PVC and stone powder are inert materials, resistant to moisture, mold, and insects. This allows SPC flooring to be widely used in damp environments like basements, SPC flooring for kitchen areas, and bathrooms, without concerns about strength degradation due to moisture, thereby avoiding potential cracking risks.

2. Mechanical Design of the Locking System: High-quality SPC flooring features precisely engineered locking mechanisms. These are not merely connection points but integral stress-dispersion systems. When correctly installed, all planks form a unified whole, distributing localized pressure over a wider area. This design effectively resists stress from daily foot traffic and furniture loads, preventing lock breakage due to stress concentration.

Professional Insight: From a material science perspective, SPC is considered one of the most stable flooring categories available today. Its inherent risk of cracking is significantly lower than that of many traditional materials. Organizations like the National Wood Flooring Association (NWFA) also recognize its advantages in stability and durability.

II. Potential Causes of Cracking: When Does Risk Shift from "Theoretical" to "Actual"?

Despite SPC's excellent performance, all materials have physical limits. In numerous international case studies, cracking problems can typically be traced to errors in one or more of the following areas.

1. Subfloor Issues: The Primary Culprit

This is the most fundamental and common cause of problems with SPC flooring. The golden rule of professional installation is: "The quality of the subfloor determines 90% of the final installation outcome."

Insufficient Flatness: This is the leading cause of lock breakage. If the subfloor (e.g., concrete) is uneven, walking or placing heavy objects creates unsupported areas under the SPC planks. Over time, this leads to fatigue stress at the locks from repeated flexing, eventually causing cracks at the lock root or even complete failure, manifesting as "V"-shaped cracks at the joints.

Subfloor Cracking or Movement: If SPC flooring is installed over a subfloor with existing structural cracks or one that is prone to movement (e.g., new concrete that hasn't fully cured and shrunk, or a structurally deficient slab), the SPC layer becomes the "victim." Cracks and movement in the subfloor generate significant stress, directly "transmitted" to the SPC planks, causing them to crack in the same locations. This is a subfloor failure, not a flooring defect.

Debris and Moisture: Sand, dust, or moisture-related subfloor protrusions create point loads, leading to stress concentration. Long-term, this can cause indentations or even micro-cracks on the plank surface.

2. Improper Installation: Human-Introduced Risk

Even the best product cannot compensate for incorrect installation.

Insufficient Expansion Gaps: While SPC has a low coefficient of thermal expansion, it is not zero. Professional installation requires leaving 8-12mm expansion gaps around the entire perimeter of the room, covered by baseboards. If the flooring is installed too tightly against walls, expansion during summer or underfloor heating operation has nowhere to go, causing planks to push against each other. This can lead to edge-lock cracking or overall floor buckling, where the buckled area may crack under excessive stress.

Forceful Installation Damaging Locks: Improper use of a tapping block and hammer during installing SPC flooring, or direct hammering, can easily cause "internal damage" to the delicate locking systems—micro-cracks invisible to the naked eye that become future failure points under pressure.

Improper Glue Application (for glue-down method): In commercial spaces or wet areas, a full-spread adhesive method is sometimes used. Using incompatible adhesive or uneven application can lead to inconsistent bonding between the floor and subfloor. Under thermal stress, this uneven adhesion can cause planks to warp or crack.

3. Extreme External Forces and Improper Use: Exceeding Design Limits

SPC flooring is designed for normal residential and commercial use.

Point Impact from Heavy Objects: While the surface is wear-resistant, the toughness of SPC (especially thinner products) is finite. Dropping sharp, heavy objects (e.g., tools) from height can generate impact energy exceeding the material's tolerance, causing local cracking.

Unprotected Furniture: High heels, hard wheelchair casters, office chair wheels, and unprotected heavy furniture legs create immense point pressure (force/area). Over time, this not only causes wear but can also lead to indentations or even cracks.

Product Quality Defects: In rare cases, low-quality SPC flooring made with excessive recycled materials or improper formulas (too high a stone powder to PVC ratio) can become brittle, significantly reducing impact resistance and toughness, making it prone to cracking even under normal use. This is relevant when understanding what SPC flooring stand for in terms of quality—Stone Plastic Composite signifies a balanced mix.

III. Professional Advice: Building a Comprehensive System to Prevent Cracking from the Source

The international professional community has established a set of best practices to ensure SPC flooring achieves its expected long service life.

1. Invest in Subfloor Preparation (The Most Critical Step!): This is the most cost-effective investment. Whether dealing with a concrete slab or an existing floor, thorough preparation is essential. For uneven concrete, using self-leveling compound is the industry gold standard. This initial investment eliminates the single biggest source of risk. This is paramount for successful installing SPC flooring on stairs (SPC flooring staircase installations) and other challenging areas.

2. Choose Products Wisely:

Look for Certifications: Select reputable brands with international certifications like AC Abrasion Class (AC3 for general residential, AC4/AC5 for commercial), FloorScore, or GREENGUARD for indoor air quality.

Consider Thickness and Structure: For environments with underfloor heating or commercial use, opt for products with greater overall thickness (e.g., >5mm) and a thicker wear layer (e.g., >20 mil) for better stability and impact resistance. This is a key consideration when evaluating SPC hybrid floors and their specific performance characteristics.

3. Hire Professional Installers: Ensure the installation team possesses professional knowledge, understands SPC's properties, and strictly follows the manufacturer's instructions and internationally recognized installation standards (e.g., NWFA guidelines). A professional team will proactively check subfloor flatness and use correct tools and methods.

4. Implement Scientific Daily Maintenance:

Protection: Apply high-quality felt pads under all furniture legs.

Mats: Place effective walk-off mats at entrances to trap abrasive grit.

Cleaning: Regularly use a microfiber mop for dry or damp mopping to promptly remove abrasive particles.

Avoid: Do not drag heavy objects; lift and carry them instead. Use protective mats under rolling chairs.