The Comprehensive Guide to PVC Wall Panels for Modern Commercial Interiors

The Comprehensive Guide to PVC Wall Panels for Modern Commercial Interiors

The global construction and interior design industries are continuously evolving, seeking materials that combine durability, cost-efficiency, and aesthetic flexibility. Among the solutions gaining significant traction, PVC wall panels have emerged as a leading choice for commercial and residential projects worldwide. This article delves into the PVC wall panel market, examining its driving forces, key benefits, emerging trends, and essential considerations for international B2B buyers.

Understanding the PVC Wall Panel Market Landscape

The demand for innovative and practical building materials has fueled substantial growth in the PVC wall cladding sector. Market analysis indicates a consistent upward trajectory, driven by the material's adaptability across diverse sectors such as healthcare, hospitality, retail, and residential construction.

A primary catalyst for this growth is the rising cost of traditional materials and skilled labor. PVC wall panels offer a compelling alternative, significantly reducing both material costs and installation time. Furthermore, increasing awareness of hygienic and low-maintenance surfaces in commercial spaces post-pandemic has accelerated adoption. Projects now prioritize solutions that are not only visually appealing but also easy to clean and disinfect, a core strength of PVC wall board products.

Key Advantages Driving B2B Specification

For business-to-business buyers, the decision to specify a material hinges on its total value proposition. PVC wall panels present a robust set of advantages.

Unmatched Durability and Moisture Resistance

Unlike traditional gypsum or wood, PVC wall panels are inherently impervious to moisture. This moisture-resistant wall panel quality makes them ideal for high-humidity environments like bathrooms, kitchens, basements, and swimming pool areas. They resist warping, rotting, and mold growth, ensuring long-term structural integrity and indoor air quality.

Cost and Time Efficiency

The installation process for interior PVC cladding is remarkably straightforward. Featuring interlocking tongue-and-groove systems or simple adhesive methods, these panels can be installed directly over existing walls, minimizing surface preparation. This translates to faster project completion and reduced labor costs—a critical factor for large-scale commercial projects.

Design Versatility and Aesthetic Appeal

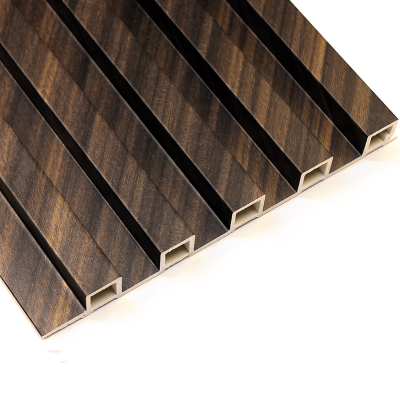

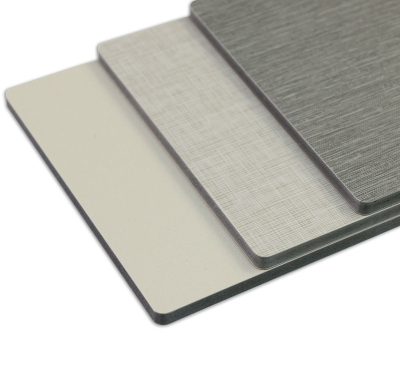

Modern manufacturing techniques allow PVC wall panels to replicate a vast array of finishes with impressive fidelity. B2B buyers can source products that mimic wood grain, natural stone, marble, or ceramic tiles. Available in countless colors, textures, and 3D designs, they provide architects and designers with extensive creative freedom for decorative wall panels.

Low Maintenance and Hygiene

The non-porous surface of a PVC wall sheet is easy to clean and requires no painting, sealing, or varnishing. A simple wipe with a damp cloth is sufficient for maintenance, reducing long-term operational costs for facilities such as hotels, hospitals, and restaurants.

Emerging Trends and Innovations

The PVC wall panel industry is not static. It is innovating to meet higher standards of sustainability and functionality.

Eco-Friendly and Recycled Materials: Responding to global environmental concerns, leading manufacturers are developing panels using recycled PVC content and ensuring products are fully recyclable at the end of their life cycle.

Enhanced Fire Retardancy: Innovations in additives have led to the development of fire-rated PVC panels, expanding their use in commercial applications where building codes mandate strict fire safety standards.

Integrated Technology: New product lines are exploring integrated features, such as acoustic insulation backings or pre-installed mounting systems for cables and fixtures, adding functional value.

Advanced Surface Treatments: Anti-bacterial coatings and anti-static surfaces are becoming more common, catering to the specific needs of healthcare, cleanrooms, and electronic manufacturing facilities.

Technical Overview and Manufacturing Insights

High-quality PVC wall panels are typically produced through a co-extrusion process. This involves melting and fusing a mixture of polyvinyl chloride (PVC), stabilizers, impact modifiers, and UV inhibitors through a shaped die to form a continuous profile. The surface layer is often printed with a high-definition decorative design and then protected by a strong, transparent wear layer.

This manufacturing process ensures uniformity, color consistency, and the integration of protective properties throughout the panel, not just on the surface. The result is a high-quality PVC panel that is dimensionally stable, scratch-resistant, and colorfast, even under prolonged exposure to light.

FAQ Section for B2B Buyers

Q1: Are PVC wall panels suitable for exterior application?

While primarily designed for interior wall cladding, certain specially formulated PVC panels are rated for exterior use. These exterior-grade panels contain enhanced UV stabilizers to prevent fading and weathering. Always verify the manufacturer's specifications for intended application before procurement.

Q2: How do I assess the quality and safety standards of PVC panels?

Reputable manufacturers comply with international standards. Key certifications to look for include ISO quality management, CE marking, and specific fire safety ratings (like Class B or similar based on regional standards). Always request test reports for fire performance, formaldehyde emissions, and mechanical properties.

Q3: What is the typical lead time for large commercial orders?

Lead times vary by manufacturer, order volume, and customization. Standard product lines may be shipped within a few weeks, while custom colors or sizes may require longer production schedules. Establishing clear communication with your supplier regarding production capacity and logistics is crucial for project planning.

Q4: Can PVC panels be installed in areas with extreme temperature variations?

PVC is known for its thermal stability. However, for uninsulated spaces subject to extreme temperature swings, it is advisable to choose panels specifically tested for such conditions and to follow the manufacturer's installation guidelines regarding expansion gaps.