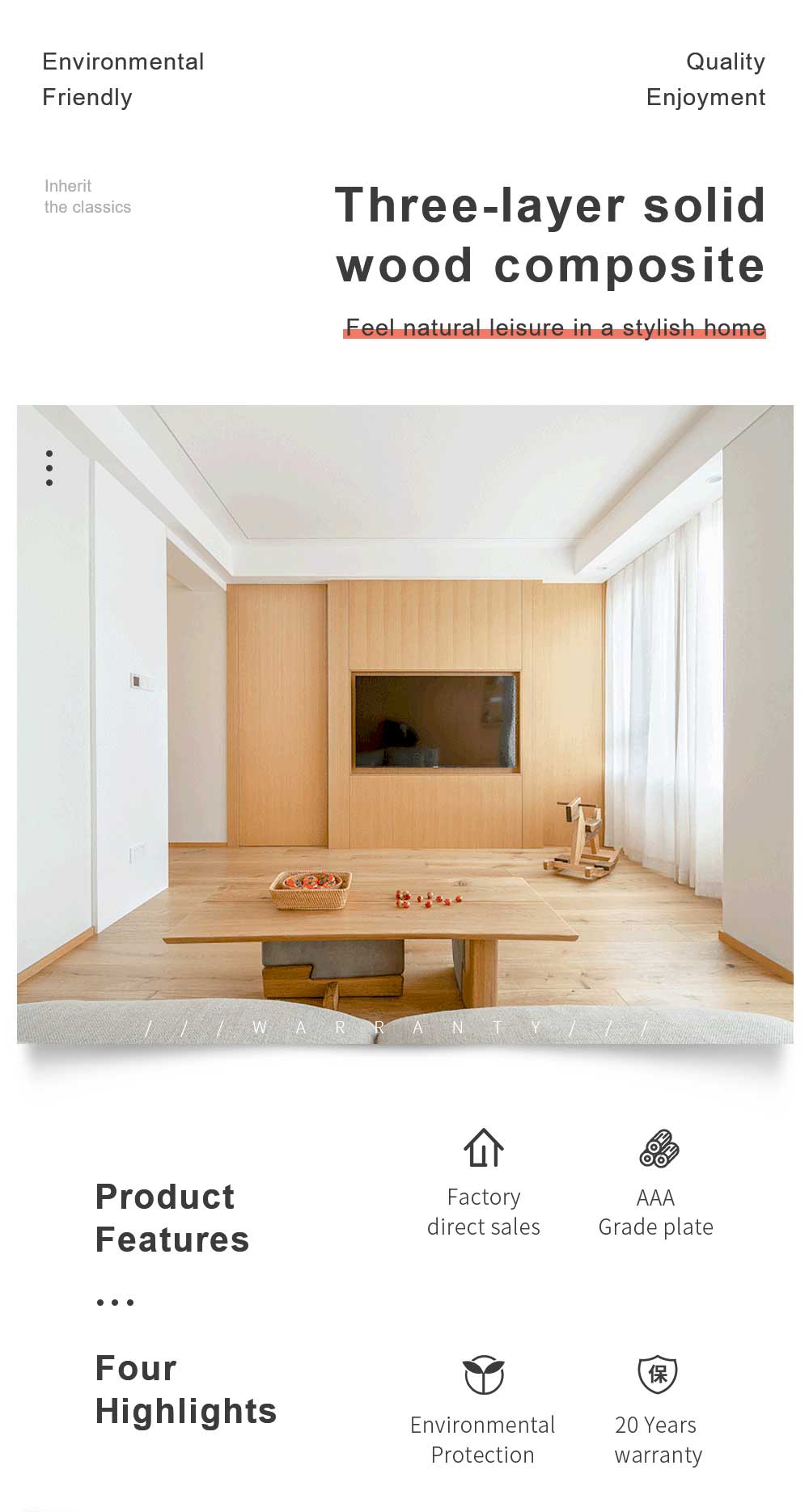

Engineered Oak Flooring

Durability: Features a robust three-layer structure that enhances stability, minimizing warping and bending.

Moisture Resistance: Suitable for both indoor and outdoor applications due to its effective moisture-proof properties.

Eco-Friendly: Manufactured using recycled wood fibers and other sustainable materials.

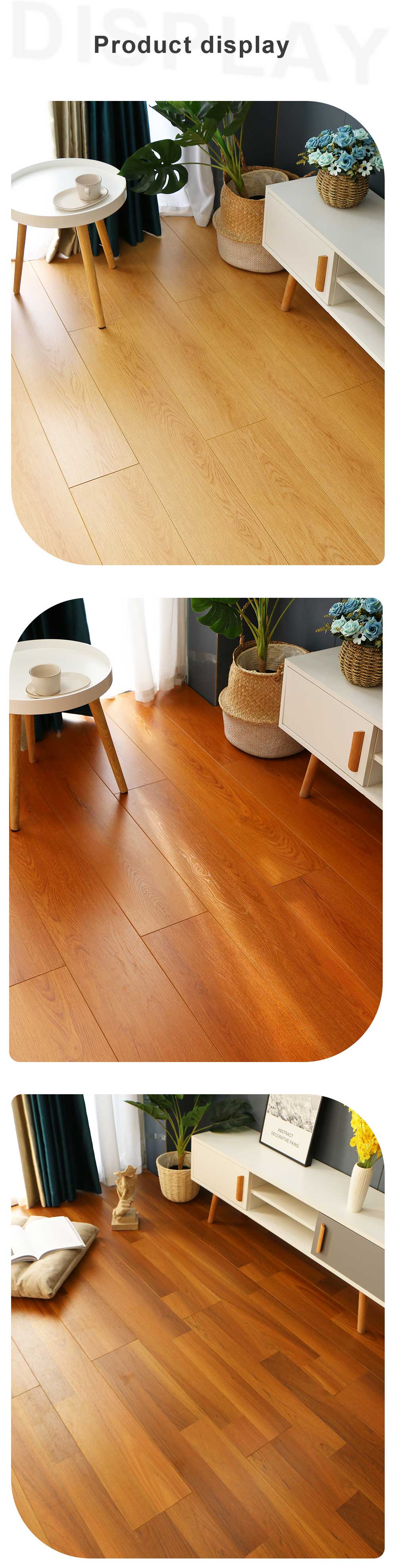

Aesthetic Appeal: Boasts a smooth texture with an authentic natural wood appearance.

Cost-Effectiveness: Offers long-term value through its durability, reducing the need for frequent replacements.

Thermal Insulation: Provides good insulation properties, contributing to energy efficiency in construction projects.

Versatility: Can be used for a variety of applications including flooring, decking, paneling, and furniture.

Engineered Oak Flooring: The Perfect Fusion of Superior Performance and Natural Aesthetics

Engineered Oak Flooring represents the pinnacle of modern flooring manufacturing technology, masterfully combining the beauty of natural oak with the stability of an engineered structure. Designed to meet the rigorous demands of global B2B buyers for quality, durability, and design versatility, this flooring solution is ideal for high-end commercial and residential projects. Its multi-layer solid wood construction not only enhances dimensional stability but also broadens its range of applications, making it a highly sought-after choice in international procurement.

Solid Wear Layer

The surface of Engineered Oak Flooring features a high-quality layer of natural oak, typically 2-6mm thick, allowing for multiple sanding and refinishing cycles. This solid oak wear layer delivers the authentic grain and texture of real wood, ensuring the floor's aesthetic appeal and long-term value.

Stabilizing Core Layer

The core is typically constructed from cross-ply high-density plywood or HDF (High-Density Fiberboard). This engineered construction effectively counteracts the internal stresses of wood, significantly improving the floor's dimensional stability in environments with fluctuating temperature and humidity. This makes it suitable for use with underfloor heating systems and in areas with higher moisture levels.

Balancing Backing Layer

A balanced backing layer further enhances the overall stability of the floorboard, preventing warping and ensuring a flat, secure installation over the long term.

Primary Applications

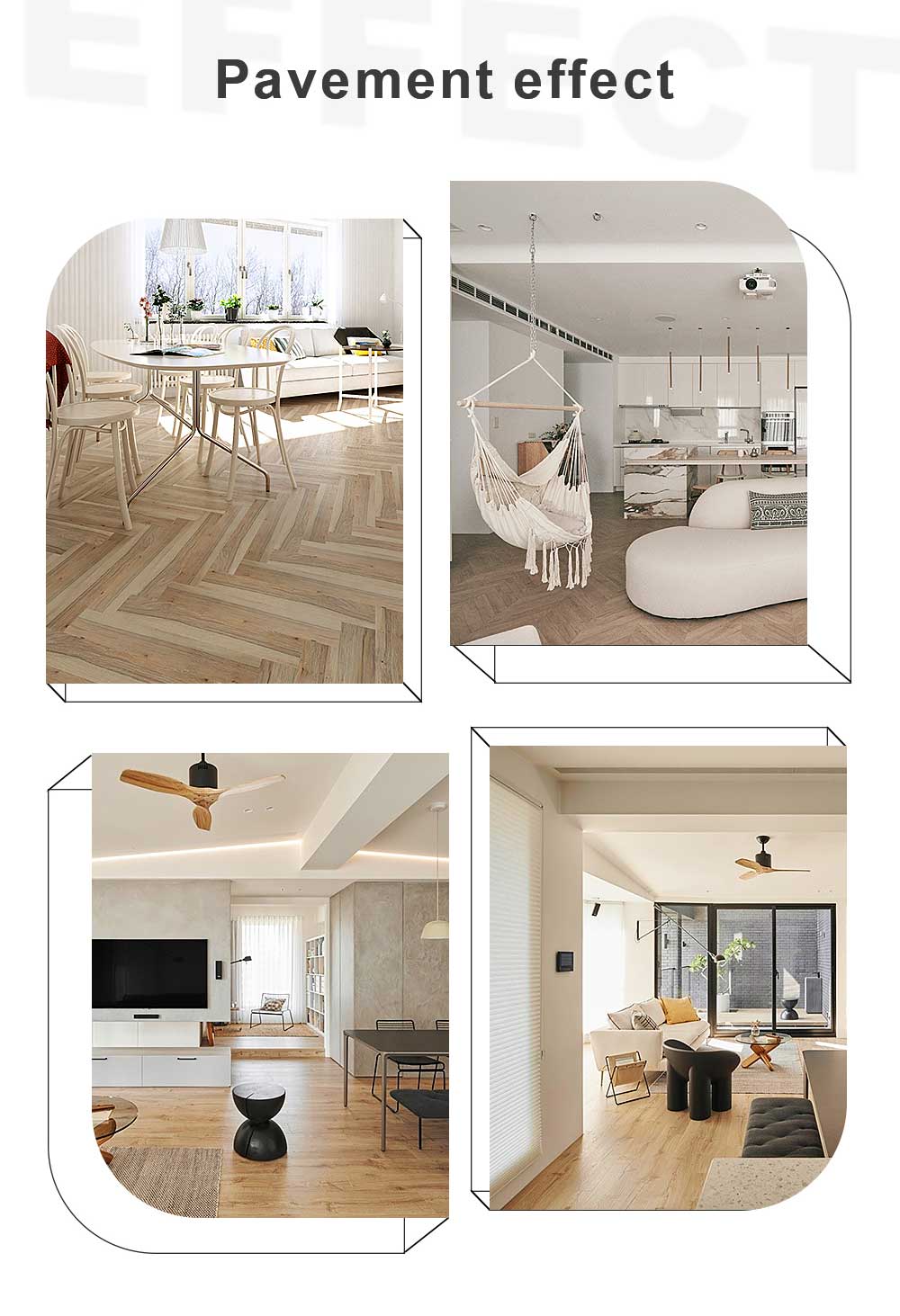

Engineered Oak Flooring is widely used in high-end retail spaces, hotels, office buildings, and residential projects. Its wide array of surface treatments (such as brushed, hand-scraped, oiled, or lacquered) and formats (including long wide planks, herringbone, etc.) can meet diverse interior design needs, creating lasting value and beauty for both commercial and residential spaces.

Durability & Ease of Maintenance

High-quality wear-resistant finishes provide the oak surface with superior resistance to scratches, stains, and UV fading. Commercial-grade engineered oak flooring typically carries an AC (Abrasion Class) rating, enabling it to withstand high levels of foot traffic. Its daily maintenance is straightforward, reducing long-term upkeep costs.

Quality Assurance and Certifications

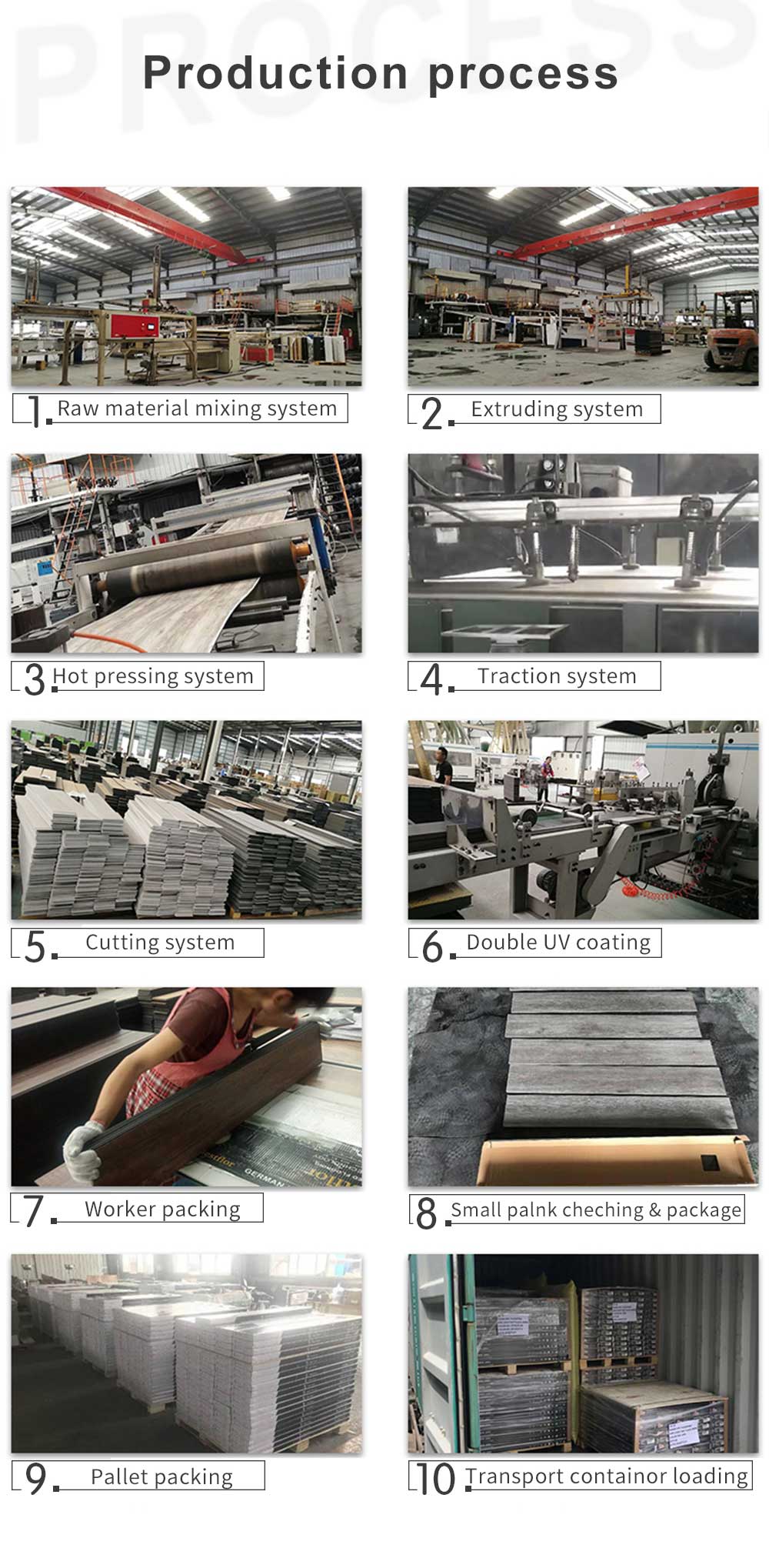

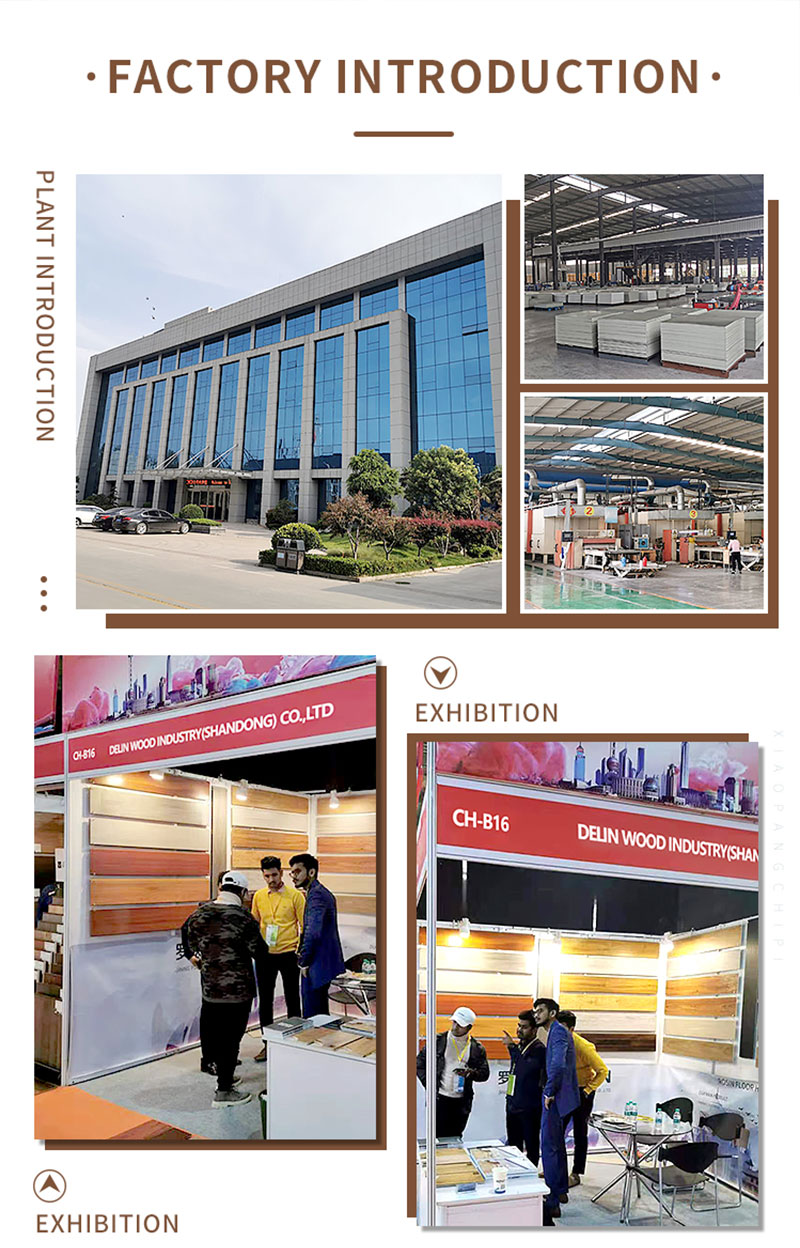

Quality is embedded in every stage of our production process. We adhere to international benchmarks, with certifications that validate our environmental management and quality control systems. The SGS certificate further assures buyers of product safety and performance. Regular audits and testing ensure that our engineered oak flooring meets or exceeds expectations, providing peace of mind for bulk purchasers.

Customization and Color Options

Understanding the diverse needs of global markets, we offer extensive customization. Clients can choose from hundreds of color options, along with custom sizes, finishes, and thicknesses. This flexibility makes our engineered oak flooring a versatile option for projects ranging from luxury residences to commercial complexes. Our design team collaborates with buyers to develop tailored solutions, enhancing project outcomes.

Installation Flexibility & Cost-Effectiveness

Engineered oak flooring supports multiple installation methods, including floating, glue-down, and nail-down, which can greatly reduce project timelines. Efficient installation systems minimize material waste and labor costs, offering predictable budgeting and scheduling for large-scale projects.

Sustainability & Certifications

The use of responsibly sourced oak and efficient material utilization makes engineered flooring an environmentally conscious choice. Most premium products hold FSC or PEFC certification and comply with international environmental standards, assisting buyers in achieving green building certification goals.

Frequently Asked Questions (FAQ)

Q1: What is the main difference between Engineered Oak Flooring and Solid Oak Flooring?

A1: The key difference lies in the construction. Engineered oak flooring features a multi-layer, cross-ply structure, providing superior dimensional stability. This makes it more suitable for use with underfloor heating, in basements, and in environments with variable humidity. Solid oak flooring is a single piece of wood, which is more susceptible to environmental changes but may allow for a greater number of sanding and refinishing cycles over its lifetime.

Q2: Is Engineered Oak Flooring compatible with underfloor heating systems?

A2: Yes, the vast majority of engineered oak flooring is recommended for use with underfloor heating systems. Its stable construction effectively resists warping caused by heat. However, it is crucial to follow the manufacturer's specific guidelines regarding maximum temperature and installation methods prior to installation.

Q3: How should I clean and maintain engineered oak floors on a daily basis?

A3: Regular cleaning with a vacuum, soft broom, or a slightly damp microfiber mop is sufficient. Avoid excessive water and standing moisture. We recommend using the wood floor cleaner suggested by the manufacturer. Use protective pads under furniture, place mats at entrances, and regularly trim pet nails to prevent surface scratches in high-traffic areas.

Q4: What is your Minimum Order Quantity (MOQ) and typical lead time for B2B procurement?

A4: Our MOQ and lead times are flexible and can be tailored to project requirements. Orders typically start at container-load quantities. Specific volumes and lead times depend on the specifications, surface finish, and total order size. Please contact our sales team for a detailed quotation and production schedule.