Stone Composite Flooring: Technical Composition, Performance Advantages and Market Trends

Stone Composite Flooring: The Engineered Solution Redefining Durability and Design

The global flooring industry is witnessing a significant paradigm shift. As architects, contractors, and property developers seek materials that masterfully balance aesthetics, performance, and value, one category is rising to the forefront: stone composite flooring. This innovative engineered product is no longer a mere alternative but a preferred choice for demanding commercial and high-traffic residential projects worldwide. This article delves into the composition, advantages, manufacturing process, and key market trends of stone composite flooring, providing B2B buyers with the insights needed to make informed procurement decisions.

Understanding the Market Shift: Why Stone Composite Flooring?

The demand for durable flooring solutions is accelerating, driven by factors such as increased commercial construction, renovation of public spaces, and a growing consumer preference for low-maintenance, long-lasting home interiors. Traditional materials like natural stone or ceramic tile, while beautiful, often present challenges including high cost, complex installation, susceptibility to cracking, and demanding maintenance.

Stone composite flooring emerges as the engineered answer to these challenges. By combining the inherent strengths of natural minerals with advanced polymer technology, it offers a synergistic product that outperforms its individual components. Market analyses consistently highlight its growing segment share, particularly in sectors like retail, hospitality, healthcare, and educational institutions, where high-traffic commercial flooring is a non-negotiable requirement.

What is Stone Composite Flooring? A Technical Breakdown

Core Composition and Layers

Stone composite flooring is a multi-layered, engineered product. Its core strength lies in its composite structure:

Wear Layer: A top coating of pure polyurethane (PU) or aluminum oxide provides exceptional resistance to scratches, stains, and wear. This layer ensures the flooring retains its appearance for years, even under intense footfall.

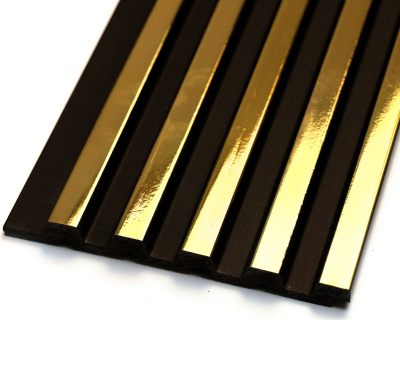

Decorative Layer: A high-resolution film or printed vinyl layer captures the authentic veining, texture, and color of natural stone, slate, or marble, offering vast design versatility.

Core Layer: The heart of the product. It is typically composed of a dense composite of calcium carbonate (limestone powder), polyvinyl chloride (PVC), and stabilizers. The high stone powder content (often 60-70%) provides rigidity, dimensional stability, and a solid, stone-like feel underfoot.

Backing Layer: A balanced backing, often from recycled materials or additional PVC, provides impact absorption, sound dampening, and stability.

Key Performance Advantages

This engineered construction translates into tangible benefits:

Superior Durability & Longevity: Highly resistant to scratches, dents, and impacts, making it ideal for heavy-duty flooring applications.

Waterproof and Moisture-Resistant: The dense, non-porous core makes it impervious to water damage, suitable for wet areas like bathrooms, kitchens, and basements.

Low Maintenance & Easy Cleaning: Requires no sealing, waxing, or special chemicals. Routine sweeping and occasional damp mopping suffice.

Installation Efficiency: Available in rigid plank, tile, or interlocking formats, it often facilitates faster, less disruptive floating floor installation over various subfloors.

Design Consistency & Range: Offers the aesthetic appeal of natural stone with greater consistency in color and pattern, plus a wider range of designer options.

From Raw Materials to Finished Product: A Glimpse into Manufacturing

The production of high-quality stone composite flooring is a precision-driven process. It begins with the meticulous selection and fine grinding of natural limestone into a powder. This powder is then compounded with PVC resins, plasticizers, and stabilizers in a high-speed mixer to create a homogeneous, dry blend.

This blend is fed into a calendering line, where it is heated and pressed between massive rollers to form a continuous, dense sheet of the required thickness. The decorative layer is then fused onto this core under heat and pressure. Following this, the ultra-protective wear layer is applied via a precision coating system and cured under UV light. Finally, the sheet is cooled, meticulously inspected for quality, cut into planks or tiles, and milled with precise click-lock or tongue-and-groove edges for seamless installation.

Future-Forward Trends in Stone Composite Flooring

Staying ahead requires understanding emerging trends:

Hyper-Realistic Aesthetics: Advances in digital printing and embossing technologies allow for stunningly realistic 3D textures and natural stone reproductions that are visually and tactilely convincing.

Sustainability Focus: Manufacturers are increasingly using recycled content in the core and backing, and the product’s long life cycle and low maintenance contribute to sustainable building projects. Look for relevant environmental certifications.

Enhanced Technical Features: Developments include integrated acoustic underlayment for sound reduction, anti-bacterial treatments for healthcare settings, and improved thermal conductivity for compatibility with underfloor heating systems.

Large-Format Planks & Tiles: The trend toward minimal seams continues, with wider and longer planks creating a more spacious, seamless aesthetic, similar to grand-format natural stone.

FAQ for B2B Buyers

Q1: How does stone composite flooring compare to luxury vinyl plank (LVP) in terms of cost and performance?

A: While both are waterproof and durable, stone composite flooring typically has a higher mineral (stone dust) content, making it more rigid, dimensionally stable, and often more resistant to indentation. It may come at a slightly higher price point than standard LVP, reflecting its enhanced performance and premium feel, positioning it as a cost-effective stone alternative for projects requiring extra robustness.

Q2: Is it suitable for commercial applications like retail stores or offices?

A: Absolutely. Its exceptional durability, low maintenance, and high aesthetic appeal make it an outstanding choice for commercial and residential flooring projects. Specific commercial-grade classifications (based on wear layer thickness) are designed to handle the heaviest foot traffic.

Q3: What is the required maintenance routine?

A: Maintenance is remarkably simple. Daily sweeping or vacuuming to remove abrasive grit, coupled with periodic damp mopping using a pH-neutral cleaner, is all that’s required. It eliminates the need for the periodic sealing and specialized treatments that natural stone demands.

Q4: Can it be installed over existing flooring?

A: In many cases, yes. Its rigid core often allows for a floating floor installation over existing, smooth, and level substrates like tile, vinyl, or concrete, provided moisture testing and proper preparation guidelines are followed. This can significantly reduce renovation time and cost.